Canadian winters bring unique challenges to power infrastructure. Extreme cold, rapid temperature fluctuations, and heavy snowfall can cripple electrical systems, causing outages when communities need power most. Transformer selection becomes crucial for renewable energy projects facing these harsh conditions.

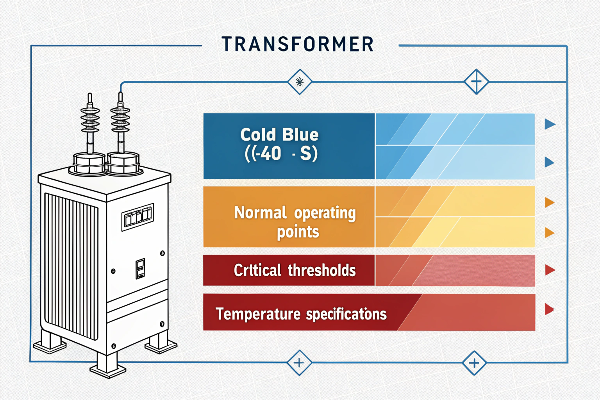

Transformers designed specifically for Canadian winters need enhanced insulation systems, specialized oils rated for extreme cold, and robust monitoring capabilities. The best transformers incorporate cold-climate modifications including silicon steel cores, special gasket materials, and expanded thermal protection to ensure reliable operation down to -40°C.

Having worked with renewable energy developers across all Canadian provinces, I've witnessed the consequences of installing standard transformers in our extreme climate. Let me share what I've learned about selecting transformers that will perform reliably through even the harshest Canadian winters, and how proper specification can save developers significant headaches and maintenance costs down the road.

Does Cold Weather Affect Transformers?

Cold weather doesn't just affect transformers - it fundamentally changes how they operate. I've seen projects where standard equipment failed within months because developers underestimated the impact of temperature extremes on their electrical infrastructure.

Cold weather impacts transformers by increasing oil viscosity, causing thermal contraction of materials, creating condensation during temperature swings, and placing stress on gaskets and seals. These conditions can lead to insulation breakdown, reduced cooling efficiency, and ultimately transformer failure if not properly accounted for in design specifications.

Through my years managing supply chains for Canadian energy projects, I've noticed that transformer failures rarely occur during the coldest days. Instead, they happen during rapid temperature changes when materials expand and contract at different rates. This creates mechanical stress on components, especially in the insulation system and at connection points.

One fascinating case study comes from our experience with oils used in our transformers. We've successfully implemented both mineral oils from Petro China and vegetable-based oils from RAPO - Chinese brands that have proven themselves in Canada's extreme conditions. These oils maintain proper viscosity even at extremely low temperatures, ensuring adequate cooling and insulation. The most remarkable aspect is how these Chinese-manufactured oils have slashed our costs significantly while maintaining exceptional cold-weather performance. This represents just one example of how strategic supplier selection can improve both performance and economics.

Transformers must also contend with snow and ice accumulation, which can block cooling systems and ventilation. Many standard designs aren't built with this in mind, leading to overheating even in cold conditions. We address this with special radiator configurations that resist ice buildup and maintain effective cooling pathways.

Insulation Considerations

| Insulation Type | Cold Weather Performance | Cost Factor |

|---|---|---|

| Standard Class H | Adequate to -25°C | Baseline |

| Enhanced Class H | Reliable to -40°C | +15-20% |

| Special Arctic Grade | Reliable to -50°C | +25-35% |

For projects in northern territories where temperatures regularly drop below -40°C, these specialized design considerations aren't optional - they're essential for operational reliability.

What Is The Minimum Operating Temperature For A Transformer?

When clients ask about minimum operating temperatures, I often see confusion about standard ratings versus actual field performance. This misunderstanding leads to expensive mistakes and premature equipment failure.

Standard distribution transformers are typically rated to operate reliably down to -25°C, while specially designed cold-climate transformers can function at -40°C or lower. The minimum operating temperature depends on insulating oil type, material selection, and design modifications that account for thermal contraction and moisture control.

In my role overseeing supply chains for Canadian energy projects, I've learned that minimum temperature ratings tell only part of the story. What matters more is how the transformer handles thermal cycling - the repeated warming and cooling that occurs throughout Canadian winters.

Our experience with Chinese-manufactured transformer oils provides valuable insights here. Both the mineral oils from Petro China and vegetable-based RAPO oils have demonstrated exceptional performance in our customers' installations across Canada's harshest environments. These oils maintain appropriate viscosity even at extreme lows, ensuring proper insulation and cooling. What's particularly noteworthy is how these Chinese options deliver this performance at significantly lower costs than many North American or European alternatives. This real-world validation has changed how we approach cold-weather specifications.

When selecting transformers for Canadian conditions, we consider several critical factors beyond simple temperature ratings. The insulation system must accommodate material contraction without creating voids or breakdown paths. Gaskets and seals require special formulations to maintain flexibility at extreme lows. Even the transformer tank itself needs design modifications to handle the mechanical stresses of thermal cycling.

Critical Cold Weather Components

| Component | Standard Version | Arctic Version Enhancement |

|---|---|---|

| Insulating Oil | Standard mineral oil | Low-viscosity formulation (like our Chinese options) |

| Cooling System | Standard radiators | Anti-icing design with increased clearances |

| Seals/Gaskets | Standard rubber | Special elastomers rated to -50°C |

| Monitoring | Basic temperature | Enhanced monitoring with low-temp alarms |

For solar and wind installations in northern regions, these specifications become even more critical as maintenance access may be limited during winter months. Proper transformer selection is not just about preventing failure but ensuring continuous operation without requiring emergency service visits during dangerous weather conditions.

Conclusion

Selecting transformers for Canadian winters requires specialized knowledge of cold-climate design factors, appropriate oil selection, and system integration considerations that go beyond standard specifications. At Voltori Energy, we engineer custom transformer solutions that deliver reliable performance in Canada's most challenging environments while optimizing your project's economics.