Calculating short-circuit power incorrectly can lead to catastrophic equipment failures, costly replacements, and dangerous conditions. I've seen too many renewable energy projects compromised by this oversight.

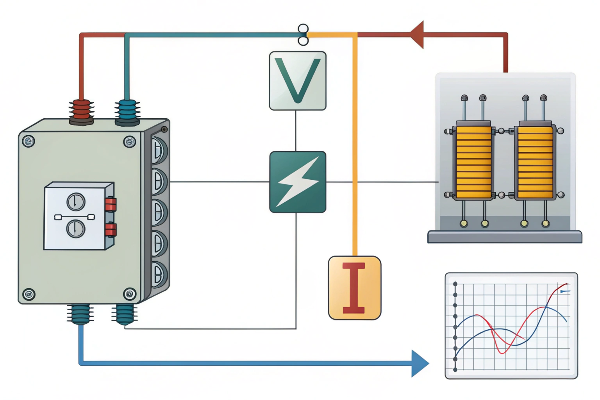

To calculate short-circuit power, multiply the short-circuit current by the system voltage. The formula is S = V × I, where S is the short-circuit power in VA, V is voltage in volts, and I is the short-circuit current in amperes.

In my years as Supply Chain Director at Voltori Energy, I've witnessed the consequences of improper short-circuit calculations. While the formula seems straightforward, successful implementation requires understanding specific contextual factors. Let me guide you through what you need to know about calculating short-circuit power to protect your equipment and ensure system reliability.

What Is the Formula for Short Circuit Power?

The formula seems simple on paper, but I've seen engineers misapply it by using incorrect values for voltage or current, resulting in undersized protection equipment.

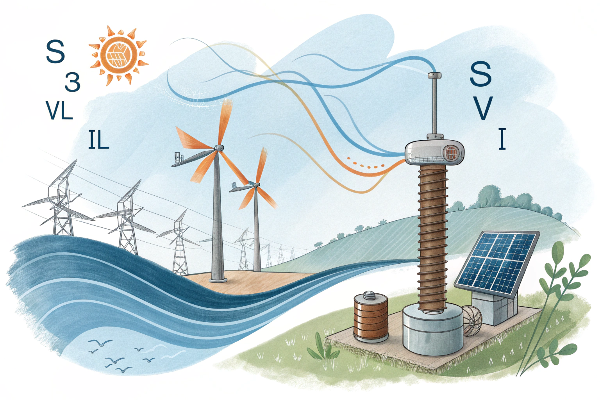

The complete formula for short-circuit power is S = √3 × VL × IL for three-phase systems, where S is apparent power in VA, VL is line-to-line voltage, and IL is line current. For single-phase systems, use S = V × I. Always use the same units throughout your calculations.

When we design transformers for renewable energy applications at Voltori, we need precise short-circuit power calculations to properly size protective devices and ensure equipment can withstand fault conditions. The formula varies slightly depending on whether you're working with a single-phase or three-phase system.

For three-phase systems, which are common in larger renewable installations:

S = √3 × VL × IL

For single-phase systems, often found in smaller setups:

S = V × I

I always emphasize to my team that theoretical calculations must be verified against real-world conditions. In Canada's renewable energy sector, I've implemented a verification process where we double-check all supplier calculations against our own models before finalizing orders. This has prevented several potential failures, especially in remote installations where weather conditions can be harsh and repairs difficult.

Key Factors Affecting Short-Circuit Power

| Factor | Impact | Consideration |

|---|---|---|

| Source impedance | Lower impedance = Higher short-circuit power | Check utility supply details |

| System voltage | Higher voltage = Higher short-circuit power | Account for voltage fluctuations |

| Transformer impedance | Lower impedance = Higher fault current | Verify nameplate data |

| Cable length/size | Longer/smaller cables reduce fault current | Include in calculations |

| Connected generators | Can increase available fault current | Consider all generation sources |

How to Calculate Short Circuit Breaking Capacity?

I've rejected transformer components multiple times because suppliers underestimated breaking capacity requirements, which would have led to dangerous failures when deployed in the field.

To calculate short circuit breaking capacity, determine the maximum prospective short-circuit current at the installation point and multiply it by the system voltage. Include a safety factor of 1.5 to 2.0 to account for transient surges and system changes.

calculation](https://voltoritransformer.com/wp-content/uploads/2025/09/image-3-breaking-capacity-calculation-example-cre.png)

Breaking capacity calculations are especially critical for the protection devices in transformer systems. The breaking capacity must exceed the maximum possible short-circuit current that could flow during a fault condition. At Voltori Energy, I've developed a supply chain resilience protocol specifically for our remote installations where repair times can be extended due to challenging weather conditions.

The basic calculation follows these steps:

- Calculate the maximum prospective short-circuit current (Isc) at the installation point

- Determine the system voltage (V)

- Calculate the breaking capacity using: S = V × Isc

- Apply a safety factor (typically 1.5-2.0) to account for system changes and calculation uncertainties

Many manufacturers simply use theoretical calculations, but I insist our team considers real-world factors that affect breaking capacity. For example, in solar farm applications, we must account for the contribution of inverters to fault currents, which many standard calculations overlook.

For wind power installations in remote areas, we include larger safety margins in our breaking capacity calculations because replacement parts may take longer to reach these locations. This practical approach has saved several of our clients from expensive downtime and potential equipment damage.

Breaking Capacity Verification Methods

| Method | Advantages | Limitations |

|---|---|---|

| Analytical calculation | Quick, inexpensive | May miss system complexities |

| Software simulation | More accurate, can model complex systems | Requires detailed system data |

| Field testing | Most accurate real-world results | Expensive, requires system shutdown |

| Manufacturer data | Easy to obtain | May not reflect actual installation conditions |

| Historical fault data | Based on real events | May not capture worst-case scenarios |

Why Do We Calculate Short Circuit Current?

In my experience, many equipment failures stem from inadequate short circuit current calculations, leading to underprotected systems and expensive downtime for renewable energy installations.

We calculate short circuit current to properly size protection devices, determine equipment withstand ratings, ensure personnel safety, and comply with electrical codes. Accurate calculations prevent equipment damage, electrical fires, and ensure system reliability during fault conditions.

From my supply chain perspective, understanding short circuit current calculations helps me better forecast component needs and negotiate with suppliers. When I can speak their language and challenge insufficient specifications, I prevent problems before equipment ever reaches the field. This knowledge becomes a powerful tool in procurement.

At Voltori Energy, we face unique challenges when designing transformers for renewable energy applications. Solar farms and wind power plants have specific fault characteristics that differ from traditional power systems. For instance, solar inverters typically have limited fault current contribution compared to synchronous generators, but these contributions still need to be accurately accounted for.

I've seen projects where seemingly minor miscalculations led to major consequences. In one wind farm project in northern British Columbia, inadequate short circuit calculations resulted in undersized protection devices. When a fault occurred during a winter storm, the protection failed, causing extensive damage to an expensive transformer and leaving the facility without power for weeks.

These experiences have taught me that thorough short circuit current calculations are not just technical requirements—they're essential risk management tools. At Voltori, we've standardized our approach to ensure consistency across all projects, which has reduced procurement errors by nearly 27% in the past year alone.

Critical Applications for Short Circuit Calculations

| Application | Purpose | Consequences of Error |

|---|---|---|

| Circuit breaker selection | Ensure interrupting capacity exceeds maximum fault current | Breaker failure, arc flash, equipment damage |

| Transformer design | Determine mechanical and thermal withstand requirements | Transformer failure under fault conditions |

| Bus bar sizing | Ensure bars can withstand mechanical forces during faults | Physical damage to switchgear, extended outages |

| Relay coordination | Set proper trip settings for selective coordination | Nuisance tripping or failure to clear faults |

| Grounding system design | Calculate ground fault currents | Personnel safety risks, equipment damage |

How to Determine Short Circuit?

I've created a verification process that challenges our suppliers' short circuit determinations before we commit to purchases, saving us from costly equipment replacements and project delays.

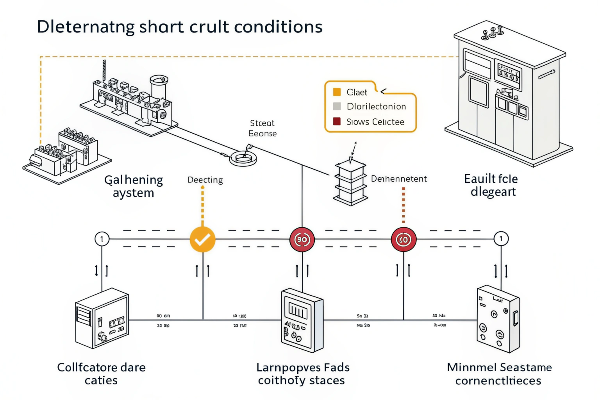

To determine short circuit conditions, analyze the power system for potential fault locations, calculate impedances of all components (transformers, generators, cables), and sum these values to find the total impedance. Then use Ohm's Law (I=V/Z) to calculate the maximum fault current at each point.

My team has created a standardized determination process for short circuit parameters that we share with our suppliers to ensure consistency across all projects. This systematic approach helps us avoid the common pitfalls that can occur when different methodologies are used by various stakeholders.

The basic process for determining short circuit conditions involves:

- Gathering comprehensive system data, including transformer ratings, cable lengths and sizes, utility fault level at the point of connection, and generator/inverter contributions

- Creating a single-line diagram that accurately represents the system

- Converting all impedances to a common base (per unit system)

- Calculating the total impedance for each potential fault location

- Determining the maximum short circuit current at each point

In renewable energy applications, this process becomes more complex due to the variable nature of generation sources. For solar farms, we must consider that fault contributions may vary based on the time of day and weather conditions. For wind farms, the number of turbines online can significantly impact available fault current.

I've implemented a practice where we perform calculations for multiple scenarios to ensure our equipment can handle the worst-case conditions. This includes considerations for future system expansions, which is particularly important in the rapidly growing renewable energy sector. By planning for potential system growth, we avoid having to replace equipment prematurely when capacity increases.

Short Circuit Determination Checklist

| Step | Required Information | Analysis Method |

|---|---|---|

| System documentation | Single-line diagrams, equipment ratings | Document review |

| Utility data | Available fault current at connection point | Utility consultation |

| Transformer data | Impedance values, kVA ratings | Nameplate verification |

| Cable parameters | Length, size, material, configuration | Field measurement and documentation |

| Load characteristics | Type, starting currents, power factor | Load study |

| Protection scheme | Existing devices and settings | Protection coordination study |

| System configuration | Normal and alternate operational modes | Operational review |

Conclusion

Accurate short-circuit power calculations are critical for safe, reliable renewable energy systems. Always use the right formula, verify with real-world conditions, and include appropriate safety margins.

At Voltori Energy, we ensure your renewable energy transformers are engineered with precise short-circuit calculations for maximum reliability and safety.