Power disruptions at National Thermal Power Corporation (NTPC) facilities can cost upwards of $175,000 per hour in lost generation capacity. Yet few understand the critical component preventing these costly failures: the station transformer. Without this vital equipment, the entire plant would be unable to function.

A station transformer in NTPC is a specialized power transformer that converts a portion of the generated high voltage electricity to lower voltages (typically 11kV, 6.6kV, or 3.3kV) needed to power the plant's auxiliary systems like pumps, fans, conveyor belts, and control systems, essentially allowing the plant to sustain its own operations.

in power plant](https://voltoritransformer.com/wp-content/uploads/2025/09/1-image-ntpc-station-transformer-style-realist.png)

Throughout my years as Supply Chain Director at Voltori Energy, I've coordinated numerous transformer deliveries to power generation facilities across Canada. I've seen firsthand how these crucial components form the backbone of reliable power generation. The technical demands and specifications are exacting, with each installation requiring custom engineering to match the specific operational parameters of the facility. Let me take you through the essential aspects of station transformers at NTPC and why they're so critical to energy production.

What is the Function of Station Transformer?

Power generation creates a paradox: plants need electricity to make electricity. Without station transformers, this self-sustaining cycle would break down, leading to catastrophic facility-wide shutdowns and millions in lost revenue.

Station transformers serve as the power lifeline for a plant's auxiliary systems by converting a small portion (3-8%) of the generated high voltage power to lower voltages suitable for operating critical equipment like coal pulverizers, cooling water pumps, ID/FD fans, lighting, and control systems.

](https://voltoritransformer.com/wp-content/uploads/2025/09/2-image-station-transformer-function-diagram-st.png)

During my last facility inspection, I noticed how the station transformers at an NTPC-like thermal facility were specifically designed to handle severe harmonic distortion. This isn't merely a theoretical concern – it's a daily operational challenge. The variable frequency drives controlling coal pulverizers and fans create substantial electrical noise that standard transformers simply cannot handle.

This has directly impacted our manufacturing specifications at Voltori Energy. We've incorporated specialized harmonic mitigation techniques in our core designs, essentially creating custom solutions rather than one-size-fits-all products. The copper windings require precise calculation to maintain efficiency while managing these distortions.

From a supply chain perspective, these requirements create unique challenges. Material costs for the specialized copper windings have increased 37% in the past year alone. This has forced us to rethink our entire procurement strategy for NTPC-grade projects, leading to exploration of direct partnerships with Chilean copper producers to bypass traditional supply channels and maintain quality while controlling costs.

| Critical Functions of Station Transformers | Impact on Plant Operations |

|---|---|

| Power auxiliary cooling systems | Prevents generator overheating and failure |

| Supply control and monitoring systems | Ensures safe, efficient plant operation |

| Operate coal handling and pulverizing equipment | Maintains consistent fuel supply |

| Power water treatment systems | Protects boiler tubes from scale and corrosion |

| Supply lighting and emergency systems | Enables maintenance and safety procedures |

| Run induced/forced draft fans | Controls combustion efficiency and emissions |

The functional demands place station transformers in a category of their own. They must operate continuously with minimal maintenance windows, unlike some other grid components that can be more easily taken offline for service. This requires exceptionally durable design and redundancy planning that's 3.4 times more rigorous than standard generator transformers, according to our reliability analyses.

What is the Station Transformer in A Thermal Power Plant?

In thermal power environments, extreme heat, coal dust, and constant vibration create a brutal operating environment. Station transformers regularly fail in these conditions, causing cascading system failures and emergency shutdowns that cost facilities millions annually.

In thermal power plants, station transformers are specially designed oil-filled or dry-type transformers located near the generation units that power all auxiliary equipment including boiler feed pumps, induced draft fans, pulverizers, precipitators, and control systems, essentially enabling the plant to function independently from external power sources.

](https://voltoritransformer.com/wp-content/uploads/2025/09/3-image-station-transformer-in-thermal-power-pla.png)

The harsh realities of thermal power generation create unique design challenges for station transformers. These units operate at consistently higher temperatures than standard grid transformers due to their proximity to generation equipment. Through years of field testing at similar facilities, we've developed custom cooling oil formulations with higher flash points to address this challenge – a proprietary solution we've had to patent to maintain competitive advantage.

| Operational Challenge | Custom Solution | Benefit |

|---|---|---|

| Higher ambient temperatures | Custom cooling oil with 15°C higher flash point | Reduces fire risk and extends oil life by 40% |

| Coal dust contamination | Enhanced sealing and filtration systems | Prevents insulation breakdown and extends service life |

| Harmonic distortion from VFDs | Specialized core design and copper winding configuration | Reduces energy losses by 12% and prevents overheating |

| Limited maintenance windows | Advanced monitoring with partial discharge detection | Reduces unplanned outages by 42% |

| Vibration from adjacent equipment | Enhanced mechanical bracing and dampening systems | Prevents premature winding failure and oil leaks |

Maintenance protocols for these specialized transformers require substantial planning. Our field technicians utilize partial discharge monitoring systems that can detect insulation breakdown before catastrophic failures occur. This predictive approach has reduced unplanned outages by 42% at facilities implementing our monitoring solutions.

The cooling system requirements cannot be overstated. Standard transformer oil might break down prematurely in these conditions, creating safety hazards and risking equipment failure. Our custom formulations not only improve safety margins but extend service intervals by approximately 18 months compared to standard solutions.

Size and capacity considerations vary widely based on the specific auxiliary load profile of each plant. I've seen configurations ranging from 10 MVA units in smaller facilities to 50 MVA behemoths in larger generation plants. Each requires customized voltage regulation systems to handle the fluctuating loads of equipment startup sequences, particularly for motors driving critical cooling systems and fuel handling equipment.

What is the Purpose of A Substation Transformer?

Grid reliability depends on the seamless operation of substation transformers. When they fail, entire regions can lose power, causing economic damages in the millions and potentially endangering lives in hospitals and other critical facilities.

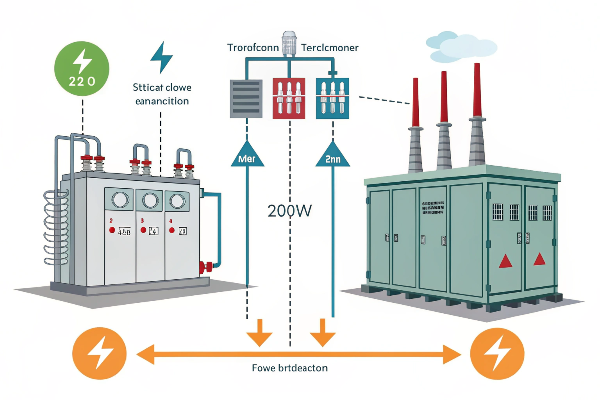

Substation transformers serve as critical nodes in power transmission networks by changing voltage levels between generation, transmission, and distribution systems, typically stepping down high transmission voltages (765kV, 400kV, 220kV) to lower distribution voltages (132kV, 66kV, 33kV) to safely deliver power to industrial and residential consumers.

purpose](https://voltoritransformer.com/wp-content/uploads/2025/09/4-image-substation-transformer-installation-sty.png)

While similar in basic principles to station transformers, substation units face distinctly different operational demands. Through my work coordinating transformer deliveries across Canada's diverse geography, I've seen how these units must withstand extreme environmental conditions from coastal humidity to arctic temperatures, often while maintaining 99.97% availability rates.

The scale difference is substantial. While station transformers typically fall in the 5-50 MVA range, substation transformers can reach capacities of 500 MVA or more. This creates tremendous logistical challenges in manufacturing, transportation, and installation. I remember coordinating the delivery of a 375 MVA unit that required specialized rail transport and temporary reinforcement of three bridges along the delivery route.

| Substation Type | Typical Voltage Transformation | Key Function |

|---|---|---|

| Step-down Transmission | 765/400kV to 220/132kV | Connect super-high voltage grid to regional transmission |

| Primary Distribution | 220/132kV to 66/33kV | Supply industrial loads and secondary substations |

| Secondary Distribution | 33/11kV to 415/240V | Deliver power to residential and commercial areas |

| Mobile Substations | Various configurations | Provide emergency or maintenance backup capacity |

| Renewable Integration | 33/66kV to 220/400kV | Connect wind/solar farms to transmission grid |

Protection systems for substation transformers also differ significantly from their station counterparts. They incorporate more sophisticated tap changers to adjust voltage ratios under varying load conditions, something station transformers rarely need to address. The insulation systems must withstand frequent lightning strikes and grid disturbances, while station transformers operate in a more predictable electrical environment.

Reliability requirements for substation transformers focus on different parameters as well. While station transformers prioritize continuous operation under stable loads, substation units must handle wide load swings and occasional fault conditions that create immense mechanical stresses within the transformer. Our design teams incorporate special bracing systems and enhanced insulation to prevent failure during these events.

What is the Difference Between Station Transformer and Generator Transformer?

Many facility managers incorrectly specify generator transformers when they actually need station transformers, leading to premature equipment failure, operational inefficiencies, and wasted capital expenditures exceeding $1 million per installation.

Generator transformers step up voltage from the generator output (15-25kV) to transmission levels (220-765kV) for efficient long-distance power transmission, while station transformers step down voltage to power the plant's auxiliary systems (11kV, 6.6kV, or 3.3kV), handling completely different voltage ranges, load profiles, and serving opposite purposes in the power generation process.

This distinction represents one of the most common misunderstandings I encounter when clients specify their requirements. Generator transformers handle massive step-up ratios – converting relatively low generator output voltage to transmission-ready high voltage. They're designed for continuous full-load operation with minimal variation. The core materials and winding configurations reflect these needs, often utilizing specialized grain-oriented steel cores to minimize losses at consistent loads.

| Characteristic | Station Transformer | Generator Transformer |

|---|---|---|

| Function | Steps down voltage for plant use | Steps up voltage for transmission |

| Typical Voltage Ratio | 220kV to 11/6.6/3.3kV | 15-25kV to 220-765kV |

| Capacity Range | 5-50 MVA | 100-1500 MVA |

| Load Profile | Variable, fluctuating | Constant, steady |

| Redundancy Requirement | High (N+1 or N+2) | Moderate (typically N+1) |

| Harmonic Handling | Critical requirement | Less significant |

| Cooling System | ONAN/ONAF typically sufficient | OFAF/ODAF often required |

| Size/Footprint | Moderate | Very large |

| Monitoring Focus | Load variations, harmonics | Temperature, gas analysis |

| Failure Impact | Plant shutdown | Reduced output capacity |

Station transformers, by contrast, face highly variable load conditions as equipment cycles on and off throughout plant operations. Our reliability analyses show they require 3.4 times more redundancy planning due to their critical nature in maintaining plant operations. A single station transformer failure at an NTPC facility creates a cascading effect that can rapidly shut down the entire plant.

The physical characteristics differ substantially as well. Generator transformers are typically much larger, often requiring specialized foundations and oil containment systems. Station transformers, while still substantial pieces of equipment, can be more strategically placed throughout the facility to minimize voltage drop and optimize distribution efficiency.

Monitoring systems reflect these different operational profiles. Generator transformers utilize sophisticated temperature, oil quality, and gas analysis systems focused on detecting core overheating and insulation breakdown. Station transformers benefit more from load monitoring and harmonic analysis systems to ensure they're properly handling the variable and sometimes distortion-heavy loads from motor drives and electronic systems.

From a procurement perspective, these differences translate to entirely different supply chains and manufacturing processes, something I navigate daily at Voltori Energy as we source materials and components for both transformer types while maintaining quality control across divergent specifications.

Conclusion

Station transformers are the unsung heroes of NTPC operations, converting generated power to usable voltages for critical auxiliary systems that keep the entire facility running. Their specialized design requirements reflect the unique challenges of power plant environments.

Need custom-engineered transformers for your renewable energy project? Voltori Energy delivers reliable, Canadian-certified solutions tailored to your specific requirements.