Excessive transformer losses cost renewable energy projects millions in wasted power generation. As operators struggle with narrowing profit margins, finding the most efficient transformer design has become critical to project viability.

The transformer design offering the lowest losses typically incorporates amorphous metal cores, copper windings, advanced cooling systems, and optimal sizing for the intended load profile. While no single design works best for all applications, these factors combined can reduce losses by 20-40% compared to standard models.

Finding the most efficient transformer design isn't merely about technical specifications—it's about understanding the specific requirements of your renewable energy project and making informed decisions that balance upfront costs with lifetime operational savings. Let me share what I've learned from our experience at Voltori Energy.

Which Transformer Has No Losses?

Power system operators frequently ask me about "zero-loss" transformers, hoping for a magical solution to efficiency problems. The reality is that physics simply won't allow it, regardless of how much we wish it were possible.

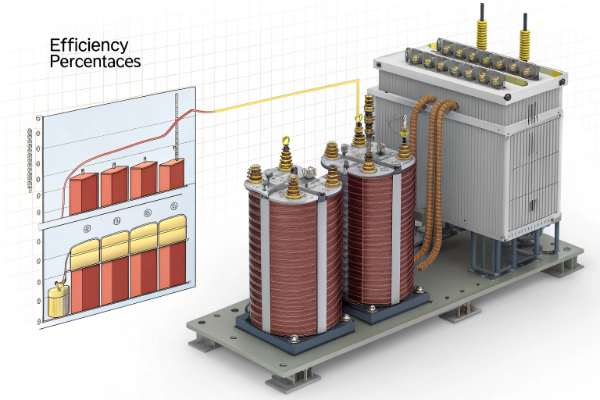

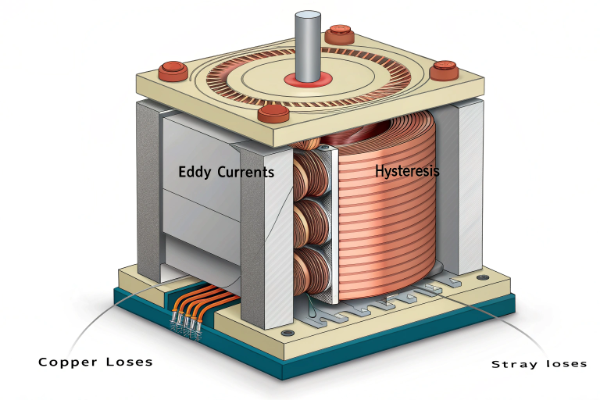

No transformer has zero losses due to fundamental physical principles. Even the most advanced designs experience core losses from magnetic hysteresis and eddy currents, along with winding losses from electrical resistance. The best modern transformers can achieve approximately 99.7% efficiency, but never 100%.

From my experience working with renewable energy clients, I've found the pursuit of "zero losses" to be counterproductive. Instead, we should focus on what's realistically achievable. At Voltori Energy, our non-crystalline alloy core transformers reduce no-load losses by 70-80% compared to traditional silicon steel designs.

This improvement comes at a cost premium of about 25-30%, but the math works out favorably for long-term projects. I recently worked with a major solar farm in Western Canada whose conventional transformers were wasting approximately $42,000 CAD annually in core losses alone. Our amorphous metal solution reduced this to around $12,000, saving them about $450,000 over the project's 15-year lifespan.

| Transformer Core Type | No-Load Loss Reduction | Cost Premium | Annual Savings* | Payback Period |

|---|---|---|---|---|

| Traditional Silicon Steel | Baseline | Baseline | Baseline | N/A |

| Amorphous Metal Core | 70-80% | 25-30% | ~$30,000 | 3-4 years |

*Based on Western Canada solar farm case study, 1000kVA transformer

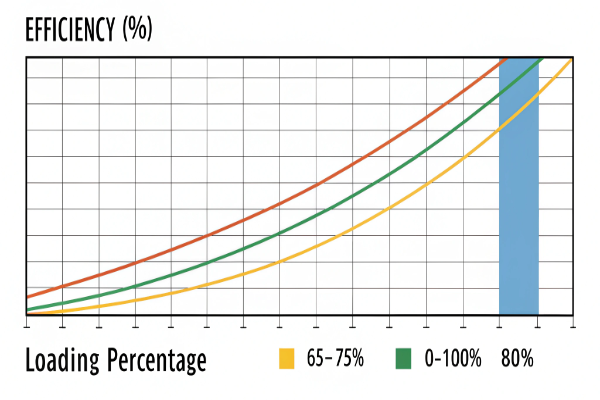

When evaluating transformer efficiency, I've learned that the operating context matters tremendously. For instance, solar farms experience different load profiles than wind farms, and this affects which design will deliver optimal efficiency. Our data shows that transformers in wind power applications actually reach peak efficiency at 65-75% of rated load rather than the conventional 80% loading level. This insight has fundamentally changed how we specify transformers for these applications.

How to Minimize Losses in Transformers?

Every time I review transformer specifications with our engineering team, I'm reminded that many renewable energy developers overlook critical design choices that could significantly reduce operational losses. These oversights translate directly to wasted revenue.

To minimize transformer losses, select low-loss core materials like amorphous metal or high-grade silicon steel, optimize conductor size and material (typically copper), ensure proper cooling systems, maintain appropriate loading levels (typically 50-80% of rated capacity), and implement regular maintenance schedules for early detection of efficiency degradation.

In my role overseeing Voltori's supply chain, I've noticed that material selection makes the biggest difference in transformer efficiency. While the initial procurement costs may be higher for premium materials, the operational savings are substantial. Our supply chain has strategically shifted toward sourcing high-grade grain-oriented silicon steel and amorphous metal cores despite their higher upfront costs.

| Loss Reduction Strategy | Potential Impact | Implementation Complexity | Cost Implication |

|---|---|---|---|

| Amorphous Metal Core | 70-80% reduction in core losses | Medium | 25-30% higher initial cost |

| High-Grade Copper Windings | 15-20% reduction in load losses | Low | 10-15% higher material cost |

| Advanced Cooling Systems | 5-10% overall efficiency improvement | Medium-High | 15-20% higher system cost |

| Optimal Sizing for Load Profile | 10-15% improvement in overall efficiency | Low | Potential cost savings |

| Regular Maintenance Program | Prevents efficiency degradation | Low | Operational expense |

When comparing material sources, I've discovered significant quality variations that affect long-term performance. Although Chinese amorphous alloy materials offer attractive pricing, our tests show that Japanese and European suppliers provide materials with better consistency and long-term performance metrics. This directly influenced our procurement strategy, as we prioritize quality and reliability over initial cost savings.

Beyond core materials, proper sizing is crucial. I've seen many installations where transformers are dramatically oversized "just to be safe," resulting in significant efficiency penalties. Based on our project data, transformers operating below 40% of rated capacity often experience disproportionately high losses relative to the power being processed. Conversely, consistently overloaded transformers suffer from excessive copper losses and accelerated insulation degradation.

Temperature management also plays a critical role in minimizing losses. We've implemented advanced cooling systems in our designs that maintain optimal operating temperatures even under variable renewable energy generation conditions. This approach has proven particularly valuable for solar installations experiencing rapid load fluctuations throughout the day.

What Type of Transformer Is the Most Efficient?

Clients frequently ask me which transformer type they should choose for maximum efficiency, expecting a simple answer. The reality is more complex and depends entirely on their specific application needs.

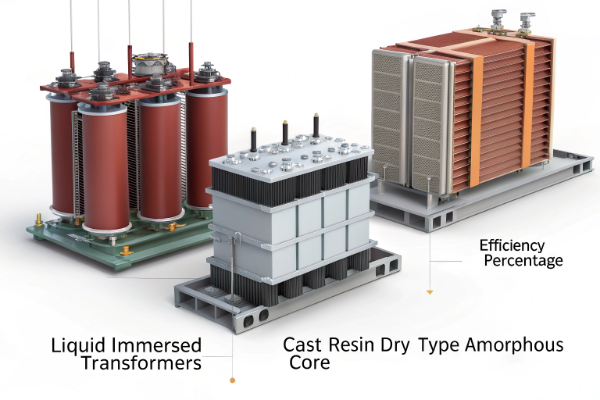

The most efficient transformer type depends on application requirements, but liquid-immersed transformers typically achieve the highest efficiencies (up to 99.5%) for large power applications. For indoor or environmentally sensitive installations, cast resin dry-type transformers offer excellent efficiency (up to 99.2%) while eliminating liquid leakage risks.

Based on my direct experience with renewable energy projects across Canada, I've observed clear patterns in transformer efficiency by type and application. Our most recent cast resin dry-type transformers achieve approximately 99.2% efficiency at 1000kVA rating, while comparable liquid-immersed designs reach about 99.5%. However, these simple comparisons can be misleading in renewable energy applications because of their variable load profiles.

| Transformer Type | Maximum Efficiency | Best Application | Key Advantages | Considerations |

|---|---|---|---|---|

| Liquid-Immersed | 99.5% | Large wind farms | Highest efficiency, better cooling | Requires containment, maintenance |

| Cast Resin Dry-Type | 99.2% | Solar farms, buildings | No liquid leaks, lower maintenance | Higher cost, slightly lower efficiency |

| Amorphous Core Liquid | 99.7% | Intermittent generation | Best no-load performance | Highest initial cost |

| Silicon Steel Dry-Type | 98.5% | Indoor substations | Lower cost, proven technology | Higher losses |

For solar farm applications, we've found that cast resin dry-type transformers often represent the best overall value despite slightly lower peak efficiency. Their reduced maintenance requirements and elimination of liquid handling concerns provide significant operational advantages. Additionally, their thermal performance characteristics align well with the daily solar generation curve.

Wind power installations present different challenges. The higher capacity factors and more continuous operation typically favor liquid-immersed designs, where the slightly higher efficiency can generate meaningful savings over time. For a 5MW wind installation operating at 40% capacity factor, the efficiency difference between transformer types can represent over $10,000 annually in recovered energy.

Newer technologies like amorphous core transformers offer particularly compelling efficiency advantages for applications with substantial no-load periods. This makes them excellent choices for renewable energy projects where generation is intermittent. The premium we pay for these high-efficiency designs typically returns multifold over the project lifetime.

What Is the 80% Rule for Transformers?

When I first joined the renewable energy sector, I accepted the conventional wisdom about transformer loading without question. Experience has taught me that blindly following rules without understanding their context can lead to suboptimal system design.

The 80% rule suggests transformers should generally operate at about 80% of their rated capacity for optimal balance between efficiency and reserve capacity. This guideline helps prevent overheating while avoiding excessive oversizing. However, for renewable energy applications with variable generation, this rule requires adjustment based on specific load profiles.

The 80% loading guideline originated from utility and industrial applications with relatively consistent loads. In my work with renewable energy systems, I've found this rule needs significant refinement. Our data shows that for wind farm transformers, peak efficiency actually occurs in the 65-75% loading range, challenging the conventional 80% target.

| Application Type | Optimal Loading Range | Efficiency at Optimal Load | Notes |

|---|---|---|---|

| Solar Farm | 60-70% | 99.1% | Daily cycling requires margin |

| Wind Farm | 65-75% | 99.3% | More consistent generation profile |

| Grid Connection | 75-85% | 99.4% | Traditional 80% rule most applicable |

| Battery Storage | 50-60% | 98.9% | Frequent fluctuations require headroom |

This insight has transformed our approach to transformer specification. Rather than automatically applying the 80% rule, we now analyze the specific load profile of each renewable energy project and optimize accordingly. For solar applications that experience daily cycling, we might select a transformer with a different loading sweet spot than for more consistent wind generation profiles.

Temperature rise considerations further complicate loading decisions. Transformers in northern Canadian installations can often be safely loaded at higher percentages than the same units in warmer southern regions. By accounting for these environmental factors, we can often specify smaller transformers without compromising reliability or efficiency.

The financial implications of proper sizing are substantial. Oversizing transformers by applying the 80% rule too conservatively increases capital costs and reduces operational efficiency. Conversely, undersizing creates reliability risks and potentially higher losses. Finding the optimal balance requires careful analysis of each project's specific conditions rather than blanket application of general rules.

Conclusion

Selecting the optimal transformer design for minimizing losses requires understanding core materials, appropriate sizing, and application-specific factors rather than seeking a one-size-fits-all solution. The ideal choice balances efficiency, cost, and reliability for your specific project needs.

At Voltori Energy, we engineer custom transformer solutions that maximize efficiency and reliability for Canada's renewable energy future.