Choosing the wrong transformer can burn your project—literally and financially. So how do you make the right choice when the stakes are this high?

To choose the right transformer, you need to consider load requirements, input/output voltages, insulation type, cooling method, and certification standards. The process starts with knowing your electrical needs and ends with engineering support.

Even if tariffs rise and trade politics heat up, the demand for reliable power in Canada won't slow down. That's why making the right transformer choice matters more than ever. If we're stuck relying on imported gear from a single source—especially the U.S.—then when the price hikes hit, the final burden lands on everyday Canadians. I believe it’s our responsibility in the energy space to think ahead and source smarter. If we don't, then we’re passing the problem down the line. Let's break down how to make a better transformer choice, not just for ourselves, but for the people who’ll feel the impact most.

How to select the right transformer?

Getting transformer specs wrong can lead to system failures, overheating, or extra costs down the road. Yet it’s still a common mistake.

You need to match the transformer to the system voltage, kVA load, phase type (single or three), and environmental conditions. Only then can you make a safe and efficient decision.

If you’re choosing a transformer for a solar project, a factory, or a simple building retrofit, the specs must match your actual need. I’ve seen projects where the transformer was too big “just in case,” and others where the voltage wasn’t rated properly. In both cases, money was wasted—and performance suffered. So here’s a better way to approach it.

Key Factors to Consider When Selecting a Transformer

| Factor | What to Check | Why It Matters |

|---|---|---|

| Voltage (Primary/Secondary) | Match to source and load | Prevents voltage mismatch or failure |

| Power Rating (kVA) | Add up total load plus margin | Ensures transformer won’t overheat |

| Phase Type | Single-phase or three-phase | Must match system setup |

| Frequency | 50Hz or 60Hz | Must align with local grid |

| Environment | Indoor or outdoor? Wet or dusty? | Helps choose enclosure and cooling |

| Certification | CSA, cUL, or utility specific | Ensures code compliance |

These aren’t just checkboxes—they are essential to system safety and efficiency. In my experience, people often underplay environmental factors. But a dusty outdoor site needs a sealed enclosure, or that transformer’s lifespan will drop fast. A CSA-certified unit is also a must if you want a headache-free inspection. Always plan for both performance and compliance.

How do I calculate what transformer I need?

Doing the math wrong means you might under-size and overheat—or overpay and overbuild. Neither helps your bottom line.

To calculate the right transformer size, take your total connected load in kilowatts (kW), convert to kilovolt-amperes (kVA), and factor in usage diversity and future load growth.

When I work with clients, the first number I ask for is their connected load. But I don’t stop there. We talk about usage patterns, standby loads, and growth expectations over 5–10 years. Without that context, you’ll either over-spec and waste money or underspec and risk failure.

How to Estimate Transformer Size

- List all electrical loads. Include motors, lighting, HVAC, and power outlets.

- Convert kW to kVA. Use the formula:

- kVA = kW / Power Factor (usually 0.8–0.9 for industrial loads)

- Add a safety margin. Usually 10–25% depending on growth expectations.

- Round up to standard kVA sizes. Common ratings include 75kVA, 150kVA, 300kVA, etc.

Let’s say your total load is 160 kW, and your power factor is 0.85:

160 / 0.85 = 188.2 kVA

Add 20% margin:

188.2 x 1.2 = 225.84 kVA

You’d round up to a 250 kVA transformer.

Simple, right? But remember—this is the start, not the end. You still need to check voltage compatibility, environmental design, and certifications. That’s where a good manufacturer or engineer helps close the loop.

How do I know which transformer to use?

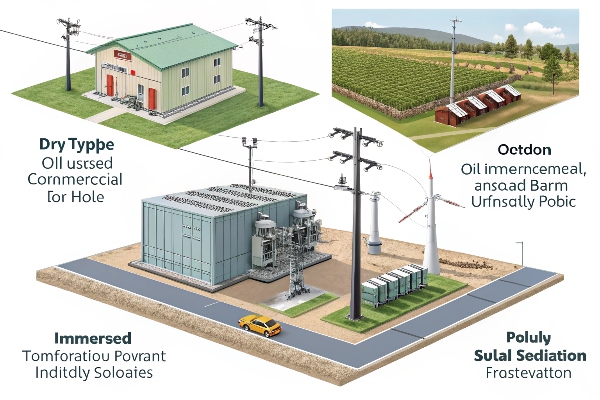

Even with good specs, picking between dry-type and oil-immersed transformers, or between pad-mount and pole-mount, can be confusing.

You choose a transformer based on load type, installation space, cooling needs, and maintenance preferences. Each use case leans toward a specific design.

Let’s say you’re building a rooftop solar plant in Toronto. You probably want a dry-type transformer—it’s cleaner, easier to inspect, and safe indoors. But for a wind farm out in Alberta? Oil-immersed is likely the better choice. It can handle higher loads, and cooling is more effective in remote outdoor settings.

Transformer Type vs Application

| Transformer Type | Best For | Notes |

|---|---|---|

| Dry-Type | Indoor, commercial, low fire risk | Easier to install and maintain |

| Oil-Immersed | Outdoor, high capacity | Better cooling, but needs oil handling |

| Pad-Mount | Ground level, secure sites | Great for solar farms or parking lots |

| Pole-Mount | Overhead lines, rural areas | Lower cost but harder maintenance |

| Auto-Transformer | Small voltage changes | Compact but no isolation |

Always consider maintenance. Oil-immersed transformers need regular checks for leaks and oil quality. Dry-types, on the other hand, need less attention but cost more upfront. Your decision will always be a trade-off, and that’s where talking to a local expert makes all the difference.

How do I know what transformer to buy?

With supply chains changing and trade rules tightening, knowing where and what to buy is now a critical part of the decision.

You should buy transformers from certified suppliers that meet Canadian standards (CSA, cUL) and who can customize to your project’s specific voltage, environment, and performance needs.

Recently, I’ve been paying a lot more attention to sourcing. With rising tariffs and the unpredictable U.S. trade climate, relying on American-made transformers is risky. The prices are going up—and not slowly. That’s why we have to actively seek alternatives from China, Turkey, India, or Vietnam. If we don’t, we’re letting regular Canadian customers carry the financial hit.

What to Look for When Buying a Transformer

| Criteria | Why It Matters |

|---|---|

| Certified to CSA/cUL | Required for legal compliance in Canada |

| Customizable specs | Ensures fit to your load and environment |

| Local engineering support | Helps with integration and troubleshooting |

| Warranty and service | Reduces lifetime maintenance risk |

| Lead times and sourcing | Avoids project delays |

Always ask your supplier: Where is it built? Is it tested to Canadian specs? Can I talk to an engineer before ordering? A good supplier won’t just give you a catalog—they’ll help you avoid costly surprises. That’s the difference between just buying a product and building a long-term solution.

Conclusion

The right transformer does more than power your system—it protects your project, your budget, and your future. Choose smart and local when possible.

Voltori Energy supplies transformers engineered for Canada—custom, compliant, and ready for the future.