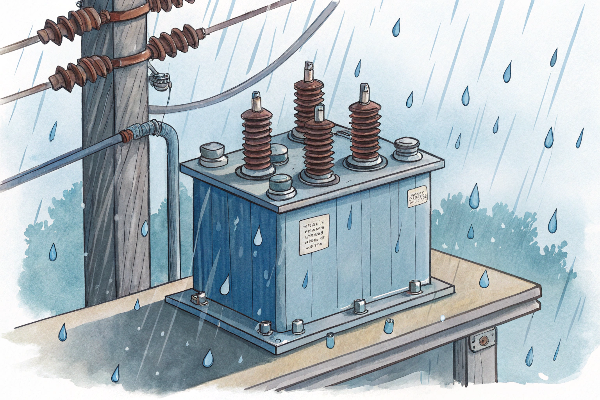

After heavy rainfall, water pooling on transformer tops can lead to serious performance issues and potential failure. Many operators don't notice the problem until it's too late, risking costly equipment damage.

To prevent water accumulation on transformers after heavy rainfall, implement a slight slope design on the transformer top with the back slightly lower than the front. This design allows rainwater to flow off naturally, preventing pooling that can lead to corrosion and electrical failures over time.

Water management might seem like a minor concern for transformers, but it's actually a critical factor affecting their longevity and performance. I've seen seemingly minor water accumulation lead to major equipment failures. Let's explore why this happens and how we can prevent it.

How does rain affect transformers?

Rain might seem harmless, but repeated exposure can deteriorate transformer housing and create entry points for moisture. I've witnessed transformers with perfect maintenance records fail simply because of unaddressed water accumulation.

Rain affects transformers by causing corrosion on external components, deteriorating gaskets and seals, and potentially entering the unit through tiny cracks. Over time, this moisture exposure can degrade insulation materials and create pathways for electrical tracking and shorts.

Water's impact on transformers goes beyond what we might initially expect. From my experience in the field, I've noticed that rainwater carries dissolved minerals and pollutants that accelerate corrosion on metal surfaces. This corrosion doesn't just affect the outer casing - it can gradually impact critical components.

The problem often starts with tiny, almost imperceptible warping of the transformer top. In theory, transformer tops should be completely flat, and they certainly appear that way in design specifications. However, the manufacturing reality can differ. If the stainless steel plates used aren't thick enough or if there are slight manufacturing errors, minor depressions can form. These depressions are nearly impossible to detect with the naked eye initially, but they become more pronounced after 6-12 months of service as thermal cycling and weight stress affect the materials.

These depressions create natural collection points for rainwater, which then sits for extended periods. Even with proper gaskets, this standing water eventually finds its way inside through microscopic pathways, especially around bolts, joints, and access panels. The situation becomes particularly concerning in areas with acid rain or in coastal regions where salt content accelerates deterioration.

What happens if water gets in a transformer?

The thought of water entering a transformer kept me awake during a severe storm last year. I'd recently inspected a client's unit that showed signs of water ingress, and the potential consequences were alarming.

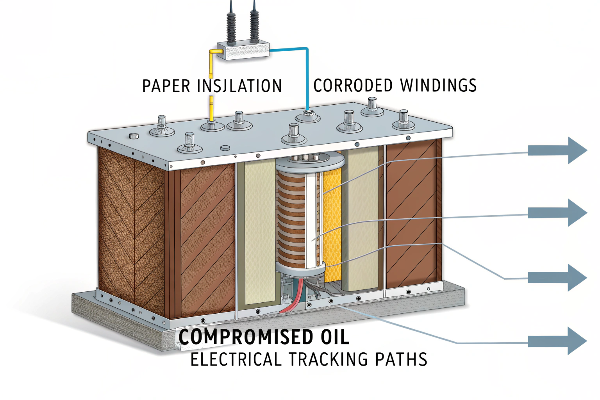

When water enters a transformer, it compromises insulation properties, accelerates internal corrosion, creates electrical tracking paths, and can cause short circuits. Even small amounts of moisture can break down the oil's dielectric properties, dramatically reducing the transformer's operational life and creating safety hazards.

Water infiltration represents one of the most serious threats to transformer functionality and longevity. Having worked on numerous transformer failure investigations, I've seen firsthand how devastating even minor moisture intrusion can be to these critical power infrastructure components.

When water enters a transformer, it initiates a cascade of destructive processes. The most immediate concern is the breakdown of insulation. Transformers rely on paper insulation impregnated with oil for their dielectric strength. Water molecules bond with cellulose fibers in the paper insulation, dramatically accelerating the breakdown of these materials. This deterioration is largely irreversible - once the paper insulation degrades, the transformer's useful life is permanently shortened.

Another significant issue is the effect on transformer oil. Water contamination reduces the dielectric strength of the oil, compromising its ability to prevent electrical breakdowns. As little as 30-50 ppm (parts per million) of water content can significantly reduce oil's insulating properties. The water also promotes oxidation and the formation of acids in the oil, which further attacks windings and internal components.

The following table shows how water affects different transformer components:

| Component | Water Effect | Potential Outcome |

|---|---|---|

| Paper Insulation | Accelerated degradation | Reduced dielectric strength, shortened life |

| Transformer Oil | Reduced insulating properties | Electrical breakdown, arcing |

| Windings | Corrosion, partial discharge | Short circuits, localized heating |

| Core | Rusting, increased losses | Efficiency reduction, overheating |

| Bushings | Tracking, flashover | Catastrophic failure, explosion risk |

Why do transformers have water in them?

This question confused me until I realized many people mistake cooling systems for water content. I've had to explain this misconception to many new technicians on my team.

Transformers don't intentionally have water in them - quite the opposite. Manufacturers go to great lengths to ensure transformers are dry during production. Any water present is unintentional contamination that enters through inadequate seals, manufacturing defects, or maintenance issues.

The confusion around water in transformers is understandable but important to clarify. Having worked in transformer manufacturing facilities, I can confirm that significant effort goes into ensuring transformers are completely dry before they leave the factory. The manufacturing process actually includes specific dehydration phases to remove moisture from all components.

For oil-filled transformers, the presence of any water is problematic and entirely unintentional. During manufacturing, transformers undergo vacuum drying processes where they're placed in special chambers and heated while under vacuum to extract any moisture from the insulation materials. After this process, the transformer is immediately filled with treated oil to prevent any reabsorption of atmospheric moisture. This oil is also specially processed to have extremely low water content - typically less than 10 ppm for new units.

Some confusion might arise because certain transformer types do use water as a coolant, but these are specifically designed "water-cooled transformers" where the water flows through sealed cooling systems and never contacts the electrical components. Even in these systems, the transformer's internal components must remain dry.

What many people observe on transformer tops after rainfall isn't designed water collection but rather an unintended consequence of manufacturing variability. In my inspections, I've found that brand new transformers often have perfectly flat tops, but after exposure to thermal cycling, mechanical stress, and environmental factors, subtle depressions form. These depressions become more pronounced over time and create collection points for rainwater.

Are transformers immune to water?

I once believed modern transformers were well-protected against water until I witnessed a three-month-old unit fail after heavy rains. The manufacturer had claimed their design was "weatherproof" but hadn't accounted for water pooling.

Transformers are not immune to water. While they have protective enclosures designed to resist normal rainfall, they're vulnerable to standing water, especially on horizontal surfaces where pools can form. Prolonged exposure to standing water will eventually compromise even well-designed sealing systems.

The relationship between transformers and water exposure is nuanced and often misunderstood, even by some industry professionals. From my experience consulting on transformer installations across various climate zones, I've learned that no transformer is truly waterproof, only water-resistant to varying degrees.

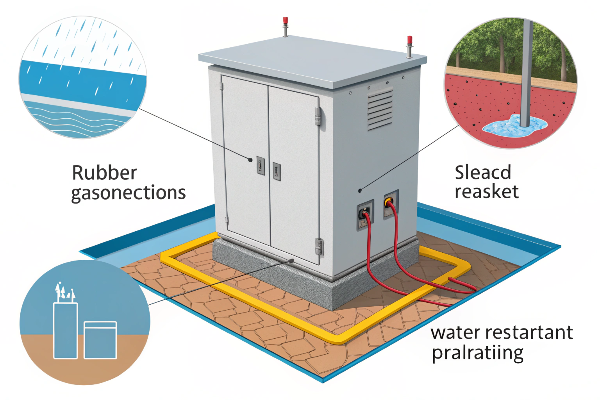

Transformer manufacturers design their equipment with environmental exposure in mind, incorporating features like rubber gaskets, sealed connections, and water-resistant paints. However, these protective measures have limitations. They're engineered primarily to withstand rain that hits and runs off, not to handle prolonged exposure to standing water.

The distinction between water resistance and water immunity becomes particularly important when considering the design of transformer tops. In theory, transformer tops should be perfectly flat according to design specifications. However, the reality of manufacturing processes means slight variations inevitably occur. Stainless steel sheets used in construction, if not thick enough or properly supported, can develop subtle depressions that are invisible to the naked eye initially.

These minor imperfections become more pronounced over the first 6-12 months of operation as the transformer undergoes thermal expansion and contraction cycles. What begins as a barely perceptible dip can eventually form a noticeable depression where water collects. During heavy rainfall, these areas become problematic water collection points rather than shedding water as intended.

This vulnerability explains why we at Voltori Energy have moved away from purely flat-top designs in our custom transformers. Instead, we implement a slight intentional gradient, typically with the back of the transformer top positioned 2-5mm lower than the front. This subtle slope is hardly noticeable visually but makes a significant difference in water management, allowing rainfall to naturally flow off rather than collect.

Conclusion

Preventing water accumulation on transformers requires intentional design with sloped tops and regular inspection for pooling areas. Don't wait for failure - address water collection proactively to extend transformer life. Voltori Energy's custom transformers feature purposeful drainage designs to protect your renewable energy investments.