Choosing the wrong transformer type could cost you thousands in unnecessary expenses and maintenance issues. Many project managers struggle with this critical decision, often lacking clear comparison points.

The right transformer choice depends on your specific application needs. Oil-filled transformers excel in outdoor and high-capacity installations due to better cooling and lower costs, while dry-type transformers are preferred for indoor, populated spaces where fire safety and environmental concerns are paramount.

I've spent years helping renewable energy projects across Canada select the appropriate transformer technology. Through this experience, I've seen firsthand how this decision impacts project timelines, budgets, and long-term operational success. Let me walk you through what you need to know to make an informed choice.

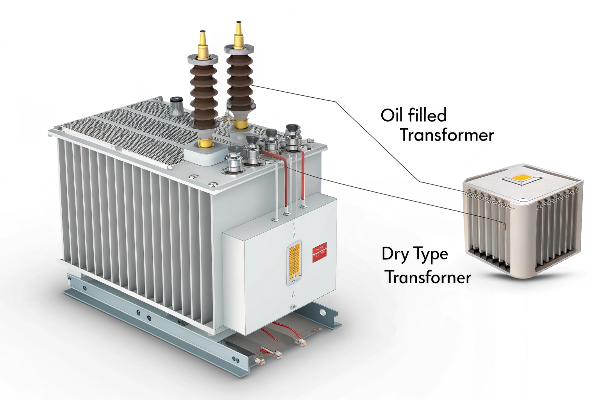

Which is better: oil-filled transformer or dry type transformer?

Projects fail when managers choose transformers based on price alone, ignoring crucial environmental factors and installation requirements that determine long-term performance.

Neither type is universally "better" - each has specific advantages. Oil-filled transformers offer superior cooling efficiency and cost-effectiveness for outdoor and high-capacity applications, while dry types provide enhanced safety and environmental benefits for indoor installations near populated areas.

When evaluating which transformer is truly "better" for your specific needs, multiple factors beyond initial cost must be considered. I've worked with dozens of renewable energy projects across Canada, and I've found that the ideal choice often depends on a detailed analysis of your installation environment, maintenance capabilities, and long-term operational requirements.

Key Comparison Factors

| Factor | Oil-Filled Transformers | Dry Type Transformers |

|---|---|---|

| Initial Cost | Generally 10-15% lower | Higher upfront investment |

| Lifespan | 30+ years with proper maintenance | 25-30 years typically |

| Maintenance | Requires oil sampling and testing | Minimal maintenance but harder to repair |

| Cooling Efficiency | Superior cooling properties | Limited cooling capacity |

| Environmental Risk | Potential for oil leaks | No risk of fluid leakage |

| Fire Safety | Higher fire risk | Better fire resistance |

| Noise Level | Generally quieter | Often louder operation |

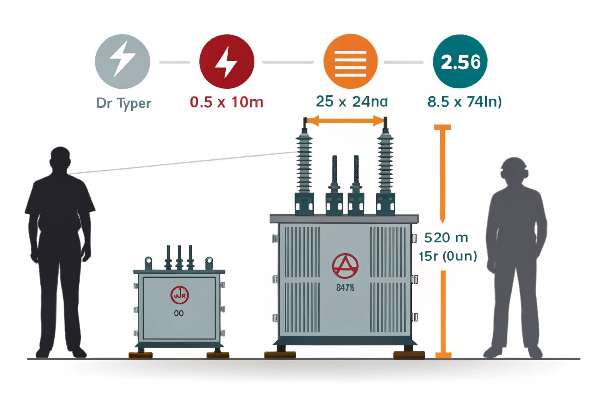

| Size/Footprint | More compact for higher ratings | Larger for equivalent ratings |

From my experience supplying transformers to Canadian renewable projects, I've observed that many clients initially consider only the purchase price, overlooking the total cost of ownership. While oil-filled units typically cost less upfront, environmental protection requirements like oil containment systems can add significant expenses. Similarly, dry-type transformers' higher initial cost is often balanced by reduced installation requirements and lower insurance premiums, especially in buildings or populated areas.

When to use an oil-filled transformer?

Many engineers have discovered too late that their installation environment isn't suitable for their chosen transformer type, leading to costly modifications and project delays.

Oil-filled transformers are ideal for outdoor installations, substations, areas with limited fire concerns, high-capacity applications (typically above 5MVA), and situations where cost-effectiveness is a priority while maintaining good cooling efficiency and longer lifespans.

I've supplied oil-filled transformers for countless renewable energy projects across Canada, particularly for solar farms and wind installations where transformers are placed outdoors in dedicated areas. These environments allow oil-filled units to showcase their strength while minimizing their potential drawbacks.

Optimal Applications for Oil-Filled Transformers

Oil-filled transformers truly shine in several key scenarios based on my experience:

-

Outdoor Installations: Their sealed construction makes them weather-resistant, perfect for Canada's harsh climate variations. I recently worked with a solar farm in Alberta where oil-filled transformers have performed flawlessly despite temperature swings from -40°C to +35°C.

-

Higher Voltage Applications: For projects requiring voltages above 35kV, oil-filled units typically offer more reliable performance. The dielectric strength of insulating oil provides excellent electrical insulation properties that dry alternatives struggle to match efficiently.

-

Cost-Sensitive Projects: When working with tight budgets, the 10-15% cost savings on oil-filled units can make a significant difference. For a recent 10MW solar installation in Ontario, this choice saved the developer approximately $50,000 in equipment costs.

-

Remote Locations: Oil-filled transformers generally require less frequent maintenance, making them suitable for installations where regular service visits are impractical. Several of our wind farm installations in remote parts of British Columbia rely on this advantage.

The weight and cooling efficiency of oil-filled transformers also makes them the preferred choice for most utility-scale renewable projects where space is available and fire risk can be properly managed through appropriate containment systems.

What are the disadvantages of dry type transformers?

Project managers who choose dry type transformers without understanding their limitations often face unexpected challenges with cooling capacity, size constraints, and much higher repair costs when issues arise.

Dry type transformers have notable disadvantages including higher initial cost (typically 15-25% more), lower overload capacity, greater size and weight for equivalent ratings, more difficult repairs, louder operation, and limitations in outdoor applications without special enclosures.

I'll be perfectly candid about dry type transformers based on my industry experience. While I haven't personally supplied many dry types to the Canadian market (I'll explain why shortly), I've gained valuable insights from clients who've used both technologies in their installations.

Key Limitations of Dry Type Transformers

The most significant disadvantages I've observed with dry type units include:

-

Cost Concerns: Frankly, the Chinese supply chain for dry type transformers doesn't offer much price advantage when shipping to Canadian markets. By the time you factor in transportation, certification requirements, and import duties, the cost savings largely disappear. This is precisely why I've focused primarily on oil-filled transformers in my business.

-

Certification Challenges: Getting dry type transformers from overseas suppliers properly certified for Canadian standards (cUL, CSA) can be particularly difficult and time-consuming. I've seen projects delayed by months due to these certification hurdles.

-

Limited Overload Capacity: Dry type transformers have less thermal mass than oil-filled units, meaning they can't handle temporary overloads as effectively. This becomes crucial for renewable energy applications where power generation can fluctuate substantially.

-

Environmental Sensitivity: Despite being promoted as environmentally friendly, dry type units are actually more sensitive to environmental conditions. They require protection from humidity, dust, and corrosive atmospheres, often necessitating special enclosures that add to the already higher cost.

-

Repair Complexity: When problems occur, repairing dry type transformers is significantly more challenging and expensive. The resin-encapsulated windings make component replacement nearly impossible in many cases, requiring complete transformer replacement instead of targeted repairs.

For these reasons, I generally recommend that clients seeking dry type transformers purchase them directly from local North American manufacturers rather than importing them.

When to use a dry type transformer?

Failing to use dry type transformers in appropriate environments has led to serious safety incidents and regulatory violations, particularly in buildings where people work or gather regularly.

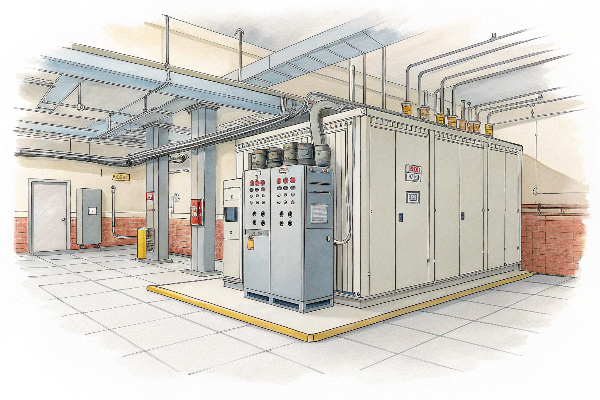

Dry type transformers are ideal for indoor installations, especially in buildings, hospitals, schools, data centers, and areas with strict fire safety requirements, environmental sensitivity, or where minimal maintenance is preferred. They excel in applications up to 5MVA where their fire-resistant properties outweigh cost considerations.

Though I primarily deal with oil-filled transformers for renewable energy applications, I've gained valuable insights about when dry type units are truly the superior choice. These situations typically involve indoor installations where safety considerations and environmental protection take precedence over cost factors.

Best Applications for Dry Type Transformers

From my experience consulting with clients across diverse projects, dry type transformers are particularly well-suited for:

- Indoor Commercial Buildings: Office buildings, shopping centers, and public facilities benefit from the reduced fire risk of dry type units. I recently advised a commercial development in Vancouver to use dry types for their rooftop solar installation specifically because the transformers needed to be housed within the building itself.

- Healthcare Facilities: Hospitals and medical centers prioritize safety above all else, making dry type transformers the obvious choice despite higher costs. These facilities simply cannot risk oil leaks or fires, and the premium for dry technology is justified.

- Educational Institutions: Schools and universities typically choose dry type transformers when installing renewable energy systems connected to their buildings. The absence of combustible liquids significantly reduces insurance requirements and simplifies regulatory approval processes.

- Food Processing Facilities: Any location where food safety is paramount generally requires dry type transformers to eliminate any risk of oil contamination. Several agricultural clients have specifically requested dry type options for this reason.

- Environmentally Sensitive Areas: Projects near water sources, conservation areas, or protected habitats often mandate dry type technology regardless of cost implications due to environmental protection requirements and potential remediation costs associated with oil spills.

These applications represent situations where the inherent advantages of dry type transformers—fire resistance, environmental protection, and minimized maintenance—clearly outweigh their higher initial cost and technical limitations.

Conclusion

Choosing between oil-filled and dry type transformers requires balancing cost, location, application requirements, and safety considerations. Your specific project needs should guide this decision rather than general preferences.

At Voltori Energy, we specialize in custom-engineered transformers for renewable energy projects across Canada, ensuring you get exactly what your system needs.