Canada's mining industry faces unique power challenges that standard electrical equipment simply can't handle. The harsh environments, remote locations, and continuous operations demand specialized solutions that many operators overlook until they face costly downtime.

Mining transformers in Canada are specially designed with reinforced insulation, enhanced cooling systems, and ruggedized enclosures to withstand extreme temperatures, dust, vibration, and humidity found in mining operations. These transformers typically feature higher short-circuit strength and superior overload capacity compared to standard models.

As Supply Chain Director at Voltori Energy, I've coordinated deliveries to some of Canada's most isolated mining operations, from the frozen north to remote mountain sites. What consistently surprises clients is not just the specialized nature of mining transformers but the complex logistics behind getting these critical components to site on schedule. Let me share what I've learned about these essential power components and why they matter so much in Canada's mining sector.

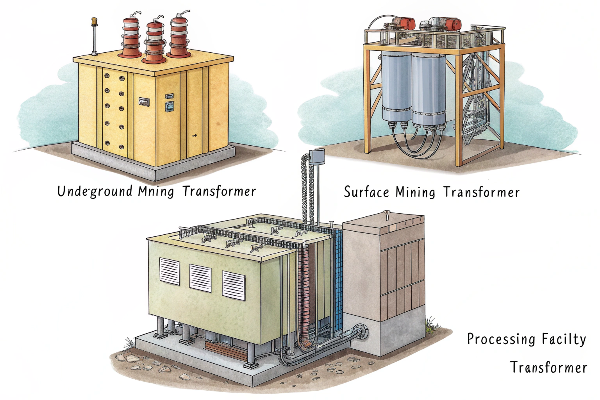

What Are The Three Types of Transformers Used In Mining?

The power demands of mining operations create serious challenges. Standard transformers frequently fail when exposed to the punishing conditions of mining environments, leading to production losses, safety hazards, and expensive emergency replacements.

Mining operations typically utilize three main transformer types: underground mining transformers (flame-proof and dust-tight), surface mining transformers (weather-resistant with advanced cooling), and processing facility transformers (specialized for controlling variable speeds and loads of mineral processing equipment).

The specialized nature of mining transformers becomes evident when you examine their construction and capabilities in detail.

| Transformer Type | Key Features | Common Challenges | Special Requirements |

|---|---|---|---|

| Underground Mining | Explosion-proof, Sealed against dust/methane | 98% humidity, Confined spaces | Specialized silicone-based insulation, Compact design |

| Surface Mining | Weather-resistant, Advanced cooling | Temperature variations (70°C+ swing), Dust accumulation | Expansion tanks, Special breathing systems, Protected cooling fins |

| Processing Facility | Load stability, Power quality control | Variable loads, Starting currents | Specialized tap changing systems, Harmonics filtration |

I remember coordinating an emergency delivery to a northern coal operation where their standard transformer failed after just three months underground. The replacement unit we provided featured specialized silicone-based insulation materials rather than standard materials, which significantly extended its operational life despite the extreme humidity environment.

Surface mining transformers must withstand temperature variations that can exceed 70°C between summer and winter in northern Canadian operations. Our design teams incorporate special expansion tanks and breathing systems that accommodate these extreme variations without compromising insulation integrity. The cooling systems must also handle dust accumulation that would quickly compromise standard cooling fins and radiators.

Who Is The World's Largest Transformer Manufacturer?

When mining operations need transformers, they often turn to global giants without considering specialized alternatives. This choice can result in equipment that meets general specifications but fails to address mining-specific requirements.

ABB, Siemens, and General Electric dominate global transformer manufacturing, with ABB leading market share at approximately 18-20%. However, specialized mining transformers often come from mid-sized manufacturers who focus specifically on ruggedized designs for extreme industrial applications rather than mass production.

The transformer manufacturing landscape has significant implications for mining operations in Canada.

| Manufacturer Type | Advantages | Limitations | Best For |

|---|---|---|---|

| Global Giants (ABB, Siemens, GE) | Consistent quality, Competitive pricing, Advanced IoT capabilities | Less design flexibility, Longer lead times for specialized units, Standard connectivity assumptions | Standard applications, Large volume orders, Digital integration |

| Mid-sized Specialists | Design flexibility, Customization for extreme conditions, Willingness to accommodate unusual specs | Higher unit costs, Limited global support network | Extreme environments, Unique specifications, Remote locations |

| Local Canadian Manufacturers | Understanding of Canadian standards, Faster response time, Easier site visits | More limited production capacity, Narrower product range | Projects requiring close collaboration, Canadian compliance focus |

From my supply chain perspective, I've observed that the mega-manufacturers typically optimize their production lines for volume efficiency, which creates longer lead times for specialized mining units that require non-standard components and testing procedures.

When a mine in northern Saskatchewan needed a transformer that could handle -50°C winter temperatures while being transportable via ice roads with weight restrictions, we found that mid-sized specialty manufacturers offered significantly more design flexibility and willingness to accommodate unusual specifications.

Selection of the appropriate manufacturer must consider not just the initial purchase price but total lifecycle costs including transportation logistics, installation requirements, and maintenance support availability.

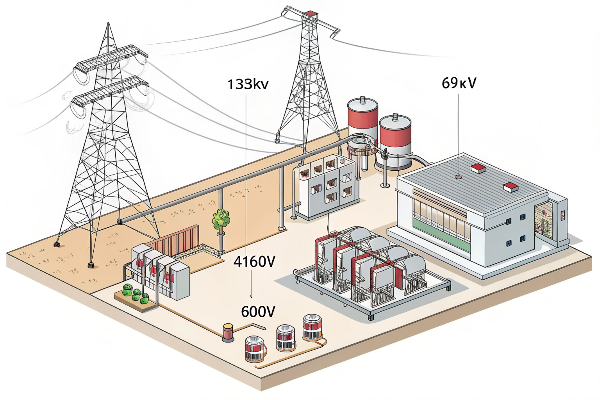

Are Transformers The Main Source Of Energy In A Mine?

Mining operators sometimes confuse power generation with power distribution, leading to misconceptions about transformers' role in their energy infrastructure. This fundamental misunderstanding can result in poor planning decisions.

Transformers are not energy sources but critical power management devices that change voltage levels for efficient distribution and safe utilization. Mines typically receive power from the grid, on-site generators, or hybrid systems, with transformers then converting this power to appropriate voltages for different mining processes and equipment.

The distinction between power generation and power transformation represents a critical concept that impacts every aspect of mining operations.

| Element | Function | Mining Considerations | Supply Chain Implications |

|---|---|---|---|

| Power Generation | Produces electrical power (grid, diesel, LNG, renewables) | Remote locations often require on-site generation, Reliability crucial | Fuel supply logistics, Generator maintenance parts |

| Power Transformation | Converts voltage levels for distribution and use | Multiple transformation stages required, Environment-specific designs needed | Specialized transformer procurement, Strategic spares placement |

| Distribution System | Moves power throughout the operation | Harsh conditions affect infrastructure durability, Expansion planning critical | Cable and switchgear sourcing, Long lead times for components |

A typical mine might generate power at 13.8kV, then use step-up transformers to reach 69kV or 138kV for efficient site-wide distribution, followed by numerous step-down transformers to provide 4160V for large motors, 600V for processing equipment, and 120/208V for lighting and control systems. Each transformation point represents a critical junction requiring specialized equipment designed for the specific application and environmental conditions.

I've worked with operations that ran into severe production delays because they added new crushing equipment without properly accounting for the increased load on aging transformers. The result was overheating, reduced transformer lifespan, and eventually unplanned outages that cost far more than a properly planned transformer upgrade would have required.

What Are The Two Types Of Transformers Used In The Industry?

Mining companies often select transformers based primarily on voltage ratings without considering the fundamental design differences that impact performance in mining environments. This oversimplification leads to premature failures.

The mining industry primarily uses oil-filled (liquid-immersed) transformers for outdoor and high-capacity applications, and dry-type transformers for indoor use where fire safety is paramount. Oil-filled units offer better cooling and longevity in harsh conditions, while dry-type models eliminate liquid leak risks in environmentally sensitive or confined areas.

Oil-filled vs. [dry-type transformers](https://www.trafo.co.za/dry-type-transformers-mining-applications/)](https://voltoritransformer.com/wp-content/uploads/2025/08/image-5.1-comparison-of-oil-filled-and-dry-type-tra.png)

The decision between oil-filled and dry-type transformers involves numerous considerations beyond basic functionality:

| Feature | Oil-Filled Transformers | Dry-Type Transformers |

|---|---|---|

| Lifespan | 30+ years | 20-25 years |

| Cooling Efficiency | Superior (better overload capacity) | Limited (more sensitive to ambient conditions) |

| Environmental Risk | Potential oil leakage concerns | No liquid leakage risk |

| Fire Safety | Requires containment systems | Inherently safer for indoor use |

| Size/Weight | Typically smaller for same capacity | Larger/heavier for equivalent rating |

| Cold Weather Performance | Excellent with proper oil | More susceptible to condensation issues |

| Maintenance Requirements | Oil testing/filtering needed | Less maintenance but more sensitive to contamination |

| Transportation Complexity | High (separate oil shipment often required) | Lower (single-piece shipment) |

| Cost | Higher initial cost, lower lifecycle cost | Lower initial cost, potentially higher lifecycle cost |

From my supply chain perspective, these two transformer categories present entirely different sourcing, transportation, and lifecycle management challenges. Transportation logistics for oil-filled units present particular challenges in mining contexts. I recall coordinating a delivery to a northern gold mining operation where the transformer oil had to be heated throughout transportation to prevent viscosity issues in -40°C conditions, then carefully filtered and tested before being introduced to the transformer once on site.

Environmental regulations create another layer of complexity. Modern oil-filled transformers typically use biodegradable oils rather than traditional mineral oils, but this shift impacts both pricing and performance specifications. These environmentally friendly oils generally cost 3-5 times more than conventional transformer oil and may require different cooling system designs.

Conclusion

Selecting the right transformers for Canadian mining operations requires specialized knowledge of both electrical requirements and environmental challenges. The wrong choice leads to costly downtime and safety risks in these demanding environments.

At Voltori Energy, we design custom transformers specifically engineered for Canada's harsh mining conditions, ensuring your operation stays powered reliably through the most challenging circumstances.