Selecting the right transformer for your renewable energy project can be overwhelming. With dozens of technical specifications to consider, sound level often gets overlooked until it's too late - creating project delays, unexpected costs, and community complaints.

The sound level of transformers is critically important as it affects regulatory compliance, community acceptance, and long-term operational viability. For projects near residential areas, excessive noise can cause project delays, trigger complaints, and require costly retrofits. Proper evaluation should occur during selection, not after installation.

I've seen this scenario play out too many times - a technically perfect transformer gets installed, only to discover its noise level exceeds community tolerance. This happened with one of our BC solar farm projects, resulting in costly delays and an additional $150,000 in acoustic treatments that could have been avoided with proper planning. Sound level considerations must be integrated into your transformer selection process from the beginning, especially for installations near noise-sensitive areas.

What Factors Should Be Considered When Selecting a Transformer?

When choosing transformers for renewable energy projects, many clients focus primarily on capacity and efficiency ratings, overlooking crucial environmental factors that can derail project timelines and budgets later on.

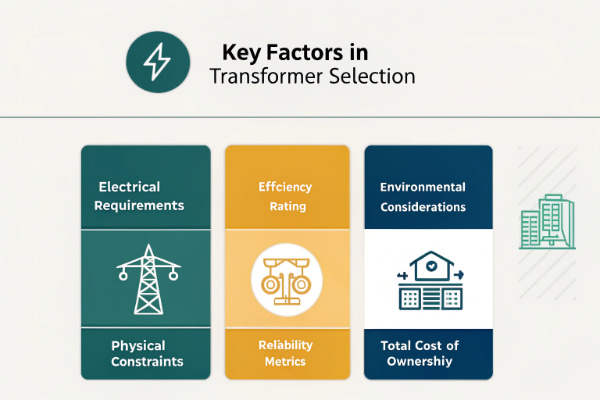

Key transformer selection factors include electrical requirements (capacity, voltage, impedance), efficiency rating, environmental considerations (sound level, operating temperature, location), physical constraints (size, weight), reliability metrics, and total cost of ownership. Each factor must be weighted according to specific project requirements.

In my experience at Voltori Energy, successful transformer selection requires a systematic approach that considers both technical and environmental factors. I've developed a comprehensive framework that goes beyond the standard specifications:

Technical Requirements Assessment

| Parameter | Considerations | Impact |

|---|---|---|

| Capacity (kVA/MVA) | Current needs plus 25-30% future growth | Undersized transformers lead to overheating and shortened lifespan |

| Voltage Requirements | Primary/secondary voltages, regulation needs | Incorrect voltage selection can damage connected equipment |

| Impedance (%Z) | Fault current limitation vs. efficiency | Higher impedance limits fault currents but may increase losses |

Environmental & Site Factors

| Factor | Considerations | Our Approach |

|---|---|---|

| Ambient Conditions | Temperature extremes, humidity, elevation | We select cooling systems based on site-specific conditions |

| Installation Location | Indoor/outdoor, proximity to personnel | Determines enclosure type and noise mitigation requirements |

| Sound Requirements | Local regulations, proximity to residences | Custom sound modeling based on actual site conditions |

For example, in our Alberta wind project, we selected a transformer with slightly higher noise levels but better cost-efficiency because the background environmental noise was already elevated. This strategic decision saved the client approximately 8% in equipment investment while still meeting all regulatory requirements.

What Is The Noise Level Test Of Transformer?

Standard transformer noise testing often fails to capture real-world conditions, leading to unexpected acoustic issues after installation that can trigger community complaints and regulatory violations.

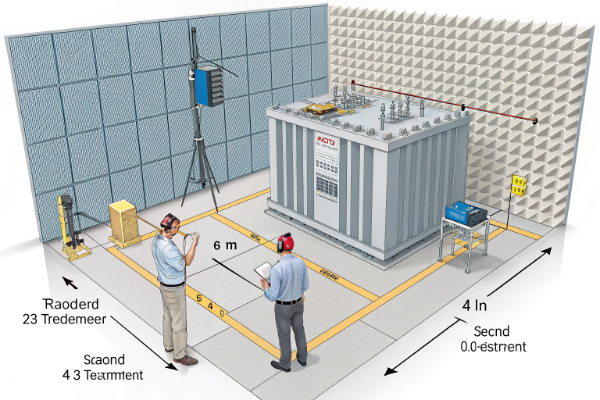

Transformer noise testing measures sound pressure levels (in decibels) at specified distances under controlled conditions. Standard tests follow IEEE C57.12.90 or IEC 60076-10 protocols and include measurements at no-load and full-load conditions, with results compared against NEMA standards for the transformer's kVA rating.

The gap between laboratory testing and real-world performance creates significant challenges in noise management. At Voltori, we've enhanced our testing protocols beyond industry standards to ensure our transformers perform as expected in actual operating conditions.

Standard vs. Enhanced Noise Testing

| Testing Aspect | Standard Industry Practice | Voltori Enhanced Protocol |

|---|---|---|

| Load Conditions | Typically at no-load and full-load only | Multiple load points (25%, 50%, 75%, 100%) to simulate realistic operation |

| Frequency Analysis | Basic A-weighted overall level | Detailed frequency spectrum analysis to identify tonal components |

| Environmental Factors | Controlled environment only | Simulated environmental conditions when possible |

| Background Noise | Requires low background noise | Differential measurements to isolate transformer noise |

I've found this approach essential after our experience with an Ontario supplier where we discovered transformers produced 3-5 dB higher noise levels under fluctuating loads compared to stable conditions. This difference can be critical for projects with strict boundary noise limitations.

Noise Sources in Transformers

Core magnetostriction creates the characteristic "hum" (primarily at twice line frequency), while cooling equipment (fans, pumps) contributes broadband noise. Load changes can cause transient noise events through winding movement or magnetic flux variations. Understanding these mechanisms allows us to recommend appropriate noise control strategies for different applications and environments.

What Is %Z On A Transformer?

Many clients struggle to understand impedance percentage (%Z) and its real-world implications, often defaulting to standard values without considering how this choice affects their overall system costs and performance.

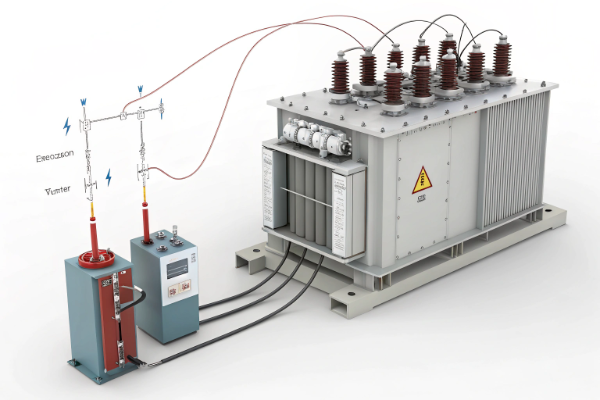

The %Z on a transformer (impedance percentage) represents the voltage drop that occurs when full load current flows through the transformer's windings. Typically ranging from 1-8% for distribution transformers, it determines fault current levels, voltage regulation, and affects parallel operation compatibility. Higher %Z values limit fault currents but may impact voltage regulation.

Impedance percentage is one of the most strategic yet overlooked specifications in transformer selection. I've seen how thoughtful impedance selection can significantly impact project economics beyond the transformer itself.

Impedance Selection: System-Wide Implications

| Aspect | Lower %Z Impact | Higher %Z Impact | Strategic Considerations |

|---|---|---|---|

| Fault Current | Higher fault currents | Better fault current limitation | May reduce costs of downstream protective devices |

| Voltage Regulation | Better voltage regulation | Poorer voltage regulation | Critical for voltage-sensitive applications |

| Efficiency | Generally better efficiency | Potential for higher losses | Impacts long-term operating costs |

| Cost Implications | Lower initial transformer cost | Higher initial transformer cost | Consider total system cost including protection equipment |

When working on a Quebec grid integration project, we deliberately selected transformers with higher impedance (6.5%) instead of standard (5.75%) models. While this increased the initial transformer cost by about 12%, it significantly reduced fault current levels, allowing downsizing of circuit breakers and protective equipment. This system-level approach ultimately saved approximately 7% in total system costs.

Parallel Operation Considerations

Transformers operating in parallel must have matched impedance characteristics to ensure proper load sharing. Even small variations in %Z can cause circulating currents, reducing efficiency and potentially causing overheating. At Voltori, we ensure impedance matching within ±2.5% for parallel units, particularly important for renewable energy applications where multiple transformers often operate in parallel during varying generation conditions.

Are Transformers Supposed To Be Loud?

There's often a significant expectation gap between what clients believe about transformer noise and technical reality, leading to disappointment and sometimes project complications when noise levels exceed anticipated levels.

Modern transformers are not meant to be excessively loud, but they do produce some noise during operation. Sound levels typically range from 45-80 dB(A) depending on size, design, and quality. NEMA standards establish acceptable noise levels based on kVA rating, with larger units generally producing more noise. Excessive noise may indicate problems requiring attention.

Managing client expectations regarding transformer noise is essential to project success. From my experience at Voltori Energy, I've developed a practical approach to noise expectations and management.

Realistic Transformer Noise Expectations

| Transformer Size | Typical Noise Level | Comparable Sound | Mitigation Options |

|---|---|---|---|

| Small (<100 kVA) | 45-55 dB(A) | Refrigerator, quiet office | Often minimal requirements |

| Medium (100-1000 kVA) | 55-65 dB(A) | Normal conversation, business office | Strategic placement, basic barriers |

| Large (1-10 MVA) | 65-75 dB(A) | Vacuum cleaner, busy traffic | Noise barriers, isolation mounts |

| Very Large (>10 MVA) | 70-80+ dB(A) | Garbage disposal, factory floor | Comprehensive acoustic enclosures |

Our 3MVA oil-immersed transformers produce around 65dB(A) at full load - comparable to normal conversation. However, we've learned that even this moderate level can trigger complaints when installed near residential areas. To address this, we provide clients with actual sound level data and case studies during the procurement phase, setting accurate expectations from the beginning.

Sound Mitigation Strategies

Prevention is always more cost-effective than remediation. Based on noise sensitivity analysis, we recommend appropriate sound control measures during the design phase: isolation pads to minimize vibration transmission, acoustic barriers positioned strategically around units, vibration dampening treatments for tank walls, and in highly sensitive installations, complete acoustic enclosures. These measures added during initial installation typically cost 30-50% less than retrofitting solutions after complaints arise.

Conclusion

Transformer sound level is not just a technical specification—it's a critical factor that can determine your project's success or failure. By considering noise requirements from the start, you'll avoid costly retrofits and community conflicts.

At Voltori Energy, we design custom transformers for renewable energy projects that balance technical performance, environmental considerations, and community needs across Canada.