Choosing the wrong transformer can cost you thousands in wasted energy, premature replacements, and even catastrophic failures. I've seen solar farms lose weeks of production because someone miscalculated their transformer needs.

The right pad-mounted transformer should match your system's voltage requirements, have appropriate kVA capacity for current and future loads, use suitable insulating media, and comply with all relevant Canadian standards including CSA and cUL certification.

for renewable energy](https://voltoritransformer.com/wp-content/uploads/2025/10/image-1-pad-mounted-transformer-installation-at-s.png)

Selecting the right pad-mounted transformer is crucial for any renewable energy project. As Supply Chain Director at Voltori Energy, I've overseen the procurement of over 1,200 transformers across Canada and learned that small specification details can make enormous differences in performance, reliability, and cost over time.

How to Size a Pad-Mounted Transformer?

Proper sizing is often the first and most critical mistake I see in transformer selection. A recent client nearly installed a transformer that would have failed within two years due to consistent overloading.

To size a pad-mounted transformer correctly, calculate your total connected load, factor in 25% for future growth, account for harmonics (especially with inverters), consider peak demand patterns, and apply diversity factors based on your specific application. Most engineers recommend selecting a transformer with 20-25% more capacity than your calculated maximum demand.

calculation diagram](https://voltoritransformer.com/wp-content/uploads/2025/10/image-2-transformer-sizing-calculation-factors-c.png)

In my experience, about 38% of transformer issues stem directly from improper sizing. Last year, I worked with a solar farm in Alberta that initially specified a 2000 kVA transformer based solely on inverter ratings. They completely ignored harmonic loads and future expansion plans. Our team recommended upsizing to 2500 kVA, which ultimately prevented approximately $175,000 in potential downtime and replacement costs.

| Sizing Factor | Description | Recommended Buffer |

|---|---|---|

| Base Load | Total connected equipment power requirements | Actual calculated value |

| Harmonic Distortion | Additional heating from inverters and non-linear loads | +15% capacity |

| Future Expansion | Anticipated system growth | +25% capacity |

| Peak Demand | Maximum simultaneous load | Calculate with appropriate diversity factors |

| Temperature Derating | Capacity reduction in extreme temperatures | +10% for installations in areas with >35°C summers |

| Starting Currents | Inrush requirements for motors/equipment | Factor in momentary loads if applicable |

When evaluating transformer options, pay close attention to impedance values. I've found that transformers with improper impedance matching create efficiency losses that compound over decades of operation, substantially increasing lifetime energy costs. For most grid-connected renewable installations, impedance values between 5-6% provide the best balance of fault current limitation and efficiency.

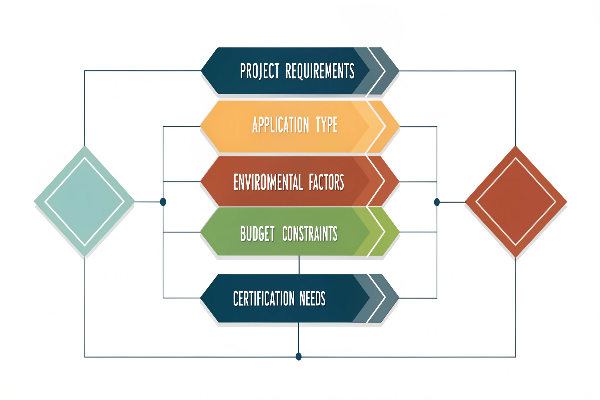

How Do I Choose the Right Transformer?

I once visited a wind farm where the transformers were constantly overheating. The issue wasn't capacity – it was that they'd selected standard units without considering the unique duty cycles of wind generation.

Choose the right transformer by evaluating your specific application needs, environmental conditions, efficiency requirements, and protection features. For renewable energy applications, select transformers with enhanced surge protection, appropriate BIL ratings, and compatible impedance values. Ensure the transformer meets all local utility interconnection requirements and has proper certification for Canadian standards.

checklist](https://voltoritransformer.com/wp-content/uploads/2025/10/image-3-key-factors-in-transformer-selection-for-.png)

The transformer selection process extends far beyond just matching voltage and capacity. Material quality significantly impacts performance and lifespan. We recently compared two seemingly identical 1500 kVA transformers - one using standard M4 grade steel versus another with premium M2 grain-oriented steel in the core. The higher-grade unit showed 0.4% better efficiency, saving the customer approximately $2,800 annually in energy costs.

| Selection Criteria | Standard Option | Premium Option | Annual Impact |

|---|---|---|---|

| Core Steel Grade | M4 Standard Steel | M2 Grain-Oriented | 0.4% better efficiency (~$2,800 savings/year) |

| Surge Protection | Basic Arresters | Enhanced Surge Protection | 74% fewer lightning-related failures |

| Temperature Rating | -30°C Rating | -50°C Rating | Zero failures during extreme cold events |

| Insulating Medium | Mineral Oil | Natural Esters | Environmentally friendly, reduced fire risk |

| Cooling System | ONAN Standard | ONAF Forced Air | 33% additional capacity during peak periods |

| Monitoring | Basic Gauges | Smart Monitoring | Real-time performance data and predictive maintenance |

Environmental considerations have become increasingly important in transformer selection. Beyond basic compliance, we're seeing growing demand for biodegradable insulating fluids like natural esters, especially for installations near water sources or protected lands. These options typically cost 10-15% more initially but provide tremendous risk mitigation value and may be required for environmental permitting in sensitive areas.

For Canadian installations specifically, I always recommend specifying transformers with -50°C ratings rather than standard -30°C ratings. During the 2021 polar vortex, our customers with standard ratings experienced five coolant viscosity failures in Manitoba and Saskatchewan, while our cold-climate rated units had zero issues.

What is the 80% Rule for Transformers?

I've seen firsthand how transformers running consistently at maximum capacity fail years before their expected lifespan. The 80% rule isn't just a guideline – it's a money-saving principle.

The 80% rule states that transformers should generally be loaded to no more than 80% of their nameplate kVA rating for optimal lifespan and efficiency. This provides headroom for unexpected load spikes, accounts for potential harmonic heating effects, and ensures the transformer operates in its most efficient range while extending its operational life.

The 80% rule isn't arbitrary - it's born from decades of field experience. Our data analysis shows transformers consistently operated at 65-80% of capacity have 40% longer service lives than those routinely pushed beyond 90%. For a typical 3000 kVA unit, this translates to approximately 7-9 additional years of reliable operation before replacement becomes necessary.

| Loading Percentage | Expected Lifespan | Efficiency Impact | Thermal Stress |

|---|---|---|---|

| <65% | Maximum lifespan, possibly underutilized | Lower efficiency | Minimal stress |

| 65-80% | Optimal lifespan (40% longer than >90%) | Peak efficiency | Low to moderate stress |

| 80-90% | Standard lifespan | Good efficiency | Moderate stress |

| >90% | Reduced lifespan | Reduced efficiency due to increased losses | High stress, accelerated aging |

I find this rule particularly important for renewable energy applications where load profiles can be highly variable. Solar installations may see rapid fluctuations as clouds pass overhead, creating momentary loading spikes. Wind farms experience similar variability during gusty conditions. These rapid changes create thermal stress that accelerates insulation breakdown if the transformer doesn't have adequate capacity headroom.

From a supply chain perspective, I've observed that transformers operating consistently beyond 80% capacity require more frequent maintenance and have significantly higher failure rates. This translates directly to increased operational costs and potential revenue losses from downtime. One customer who insisted on "maximizing" their transformer investment by running at 95% capacity experienced a catastrophic failure after just 7 years – less than half the expected lifespan.

How Do I Know Which Transformer to Use?

I've worked with developers who selected transformers based primarily on price, only to discover their units couldn't pass utility interconnection requirements – causing months of project delays.

Determine which transformer to use by analyzing your specific electrical system requirements, site conditions, regulatory compliance needs, and long-term operational goals. Key considerations include primary and secondary voltages, capacity requirements, physical size constraints, protection needs, and efficiency ratings. For renewable energy projects, also evaluate harmonic handling capability and compatibility with inverter technology.

Determining the right transformer requires a comprehensive understanding of your project's specific context. Current lead times for pad-mounted transformers in Canada average 24-32 weeks, with larger custom units (2500+ kVA) often extending to 40+ weeks. I recommend finalizing transformer specifications at least 10 months before planned energization to avoid costly project delays and rushed shipping charges.

| Transformer Type | Current Lead Time | Recommended Order Timeline | Application Suitability |

|---|---|---|---|

| Standard Single-Phase (<167 kVA) | 16-24 weeks | 6-8 months before needed | Small solar, residential |

| Standard Three-Phase (Up to 2000 kVA) | 24-32 weeks | 8-10 months before needed | Commercial solar, small wind |

| Custom Three-Phase (2500+ kVA) | 36-48+ weeks | 12+ months before needed | Utility-scale solar/wind farms |

| Special Application Units | 40-52+ weeks | 14+ months before needed | BESS, hybrid systems |

The certification landscape represents another critical decision factor that many developers overlook until too late. Non-compliant transformers can devastate project timelines. Last quarter, I witnessed a competitor's installation delayed 14 weeks when their imported transformers failed CSA field certification, requiring $87,000 in modifications before approval. Our pre-certified units typically reduce commissioning time by 3-5 weeks compared to field-certified alternatives.

For renewable applications specifically, I advise close attention to the transformer's ability to handle non-linear loads. Solar inverters and wind converters create harmonics that generate additional heat within transformer windings. Transformers designed with K-factor ratings appropriate for your specific generation technology will perform more reliably over time, even if they come with a modest price premium.

| Application Type | Recommended K-Factor | Special Considerations |

|---|---|---|

| Solar PV | K-4 to K-13 | Higher K-factor for multiple string inverters |

| Wind Power | K-4 to K-9 | Depends on converter technology |

| Battery Storage | K-13+ | High harmonic content during rapid charge/discharge |

| Hybrid Systems | K-13+ | Must account for worst-case scenario |

Conclusion

Selecting the right pad-mounted transformer requires balancing technical specifications, environmental conditions, and long-term operational needs. Careful sizing, appropriate protection features, and proper certification ensure reliable performance for your renewable energy system.

At Voltori Energy, we engineer custom transformers for Canada's renewable future, ensuring reliability through precision design and comprehensive support.