Power transformers are complex and expensive. Many businesses overspend on transformer components without understanding what they're buying. This costs you money and efficiency in your energy projects.

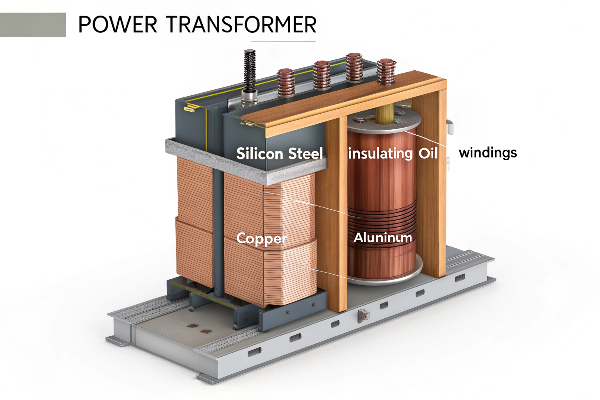

A power transformer consists of five main parts: the core (made of silicon steel), tank (steel construction), insulating oil (mineral or vegetable-based), windings (copper or aluminum), and accessories. Each part serves a specific function in the voltage transformation process.

As someone who has supplied transformers for years, I've noticed that understanding the basic components helps project managers make better decisions. Let's break down these essential parts and their cost implications so you can make smarter choices for your next power project.

What are the components of a power transformer?

When planning a transformer purchase, most people focus only on power ratings while overlooking crucial components. This oversight often leads to compatibility problems and unexpected expenses down the road.

Power transformer components include the core, tank, windings, insulating oil, bushings, tap changers, cooling systems, protection devices, and monitoring equipment. These components work together to efficiently transform voltage while ensuring safety and reliability.

labeled](https://voltoritransformer.com/wp-content/uploads/2025/07/image-2-design-a-flat-design-style-flat-design-i.png)

From a cost perspective, understanding transformer components has saved my clients thousands on their energy infrastructure projects. Below is a breakdown of the main components and their typical cost contribution:

| Component | Material | Cost Percentage | Notes |

|---|---|---|---|

| Core | Silicon Steel | 25% | Determines three-phase or single-phase configuration |

| Tank | Standard Steel | 20% | Standard welded steel construction |

| Tank | Stainless Steel (#304 or #409) | 30% | Premium option for corrosive environments |

| Insulating Oil | Mineral Oil | 10% | Standard option |

| Insulating Oil | Domestic Plant Oil (PetroChina) | 20% | Environmentally friendly alternative |

| Insulating Oil | Premium Plant Oil (FR3) | 25% | Top-tier biodegradable option |

| Windings | Aluminum | 9% | Cost-effective option |

| Windings | Copper | 27% | Premium option with better conductivity |

| Accessories | Domestic Brands | Variable | Cost-effective for non-critical applications |

| Accessories | Premium Brands | Variable | Higher cost for critical applications |

I remember working with a solar farm client who initially specified stainless steel tanks for all their transformers - after explaining the cost implications, they reconsidered this specification for non-exposed units, saving nearly $80,000 on their project.

What are the primary parts of a transformer?

Many engineers I consult with are surprised to learn that the material choices for transformer components dramatically affect both price and performance. Without this knowledge, they risk paying premium prices for features they don't need.

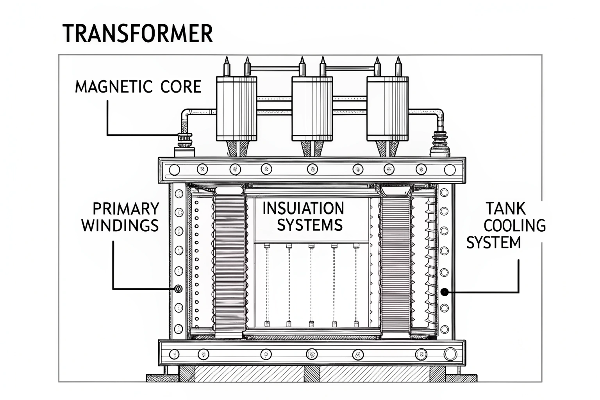

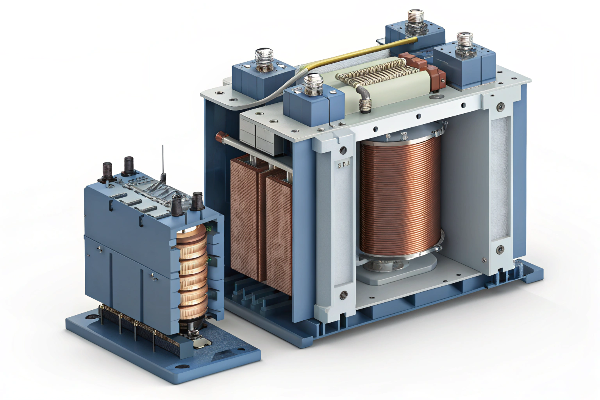

The primary parts of a transformer include the core (magnetic circuit), windings (electrical circuit), insulating materials, tank or container, and cooling system. The core and windings are the most fundamental, working together to facilitate electromagnetic induction and voltage transformation.

The core and windings represent the heart of any transformer system. Here's how they function and their cost implications:

| Primary Part | Function | Material Options | Cost Impact |

|---|---|---|---|

| Core | Provides magnetic path for flux | Silicon Steel | 25% of total cost |

| Primary Windings | Receives input voltage | Copper (+18% cost) or Aluminum | Creates magnetic field |

| Secondary Windings | Outputs transformed voltage | Copper (+18% cost) or Aluminum | Induced by magnetic field |

| Insulation | Prevents short circuits | Paper, enamel, oil | Determines temperature class |

| Tank | Houses and protects components | Steel (standard) or Stainless (+10% cost) | Provides structural support |

I've guided numerous renewable energy clients through this decision process. For a recent wind farm project, the client initially specified copper windings for all transformers based on conventional wisdom about copper's superior conductivity. After analyzing their specific load profiles and environmental conditions, we determined that aluminum windings would perform adequately for their application while saving approximately 18% on material costs. This translated to over $120,000 in savings across their multi-unit order.

What are the essential parts of a transformer?

I've seen companies spend thousands extra on premium transformer features they'll never use, while others cut corners on truly essential components. Both mistakes are costly in different ways.

Essential transformer parts include the magnetic core, primary and secondary windings, insulation systems, cooling mechanisms, and protective devices. These components are critical for the basic operation of transformers, ensuring efficient voltage conversion while maintaining safety standards.

Beyond the core, tank, and windings, accessories represent a significant cost factor that many clients overlook. Here's a breakdown of essential accessories and their functions:

| Essential Accessories | Function | Cost Considerations |

|---|---|---|

| Bushings | Connect internal windings to external circuits | Premium brands cost 2-3× more than domestic options |

| Tap Changers | Adjust turns ratio for voltage regulation | Off-load vs. on-load (3-4× more expensive) |

| Protection Relays | Monitor conditions and prevent failures | Digital systems cost 5× more than basic protection |

| Cooling Systems | Manage operating temperature | ONAN (base cost) vs. ONAF (+15%) vs. OFAF (+40%) |

| Monitoring Equipment | Track transformer performance | Basic gauges vs. advanced monitoring systems (+25%) |

I once worked with a commercial solar developer who insisted on all premium-brand accessories for their transformers. After reviewing their operational requirements, we identified opportunities to use domestic accessories for non-critical functions while maintaining premium components for key protection systems. This hybrid approach reduced their transformer costs by 15% without compromising system reliability.

What are the basics of power transformers?

When I talk with clients new to power infrastructure, they're often overwhelmed by technical specifications and industry jargon. This confusion frequently leads to overspecifying or underspecifying their transformer needs.

The basics of power transformers cover their operational principles (electromagnetic induction), key parts (core, windings, insulation), ratings (kVA/MVA capacity, voltage ratio), cooling methods (dry-type or liquid-filled), and installation requirements. Understanding these fundamentals helps in selecting the right transformer for specific applications.

Understanding transformer basics from a cost perspective helps in making informed decisions. Here's a comparison of fundamental transformer types and considerations:

| Basic Consideration | Options | Cost Implications | Application Factors |

|---|---|---|---|

| Transformer Type | Liquid-filled | Lower cost per kVA | Outdoor installations, higher ratings |

| Transformer Type | Dry-type | Higher cost per kVA | Indoor use, areas with flammability concerns |

| Core Construction | Shell-type | Higher material cost | Better short-circuit strength |

| Core Construction | Core-type | Lower material cost | Standard applications |

| Cooling Method | ONAN (Oil Natural, Air Natural) | Base cost | Lower capacity |

| Cooling Method | ONAF (Oil Natural, Air Forced) | +15-20% cost | +25-30% capacity over ONAN |

| Cooling Method | OFAF (Oil Forced, Air Forced) | +35-40% cost | +50% capacity over ONAN |

| Insulation Class | Standard | Base cost | 105°C temperature rise |

| Insulation Class | Premium | +10-15% cost | 80°C temperature rise, longer life |

I've guided clients through this decision process by analyzing their specific installation environment, maintenance capabilities, and budget constraints. In one manufacturing facility project, the initial specification called for dry-type transformers throughout the plant. By recommending oil-filled units for outdoor locations, we reduced their transformer budget by approximately 22% while maintaining the necessary safety standards for their indoor applications.

Conclusion

Understanding transformer components helps you make cost-effective choices without sacrificing quality. The core, tank, oil, windings, and accessories each impact both performance and price significantly. Voltori Energy delivers custom-engineered transformers for renewable energy applications, ensuring the perfect balance of value and performance for your Canadian projects.