Power transformer explosions are devastating events that can plunge communities into darkness and cost millions in damages. As I've witnessed throughout my career in the energy sector, these failures aren't just inconvenient—they represent critical points of vulnerability in our power infrastructure.

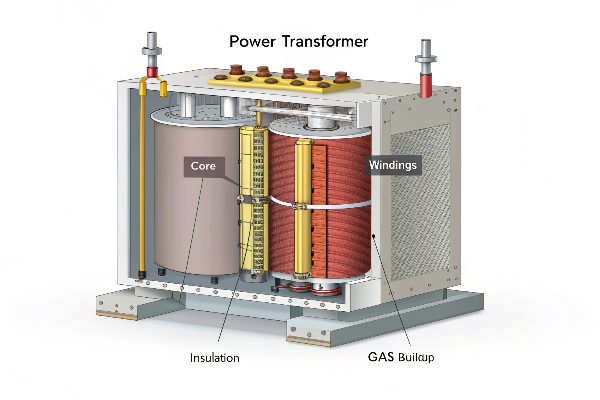

Power transformers explode primarily due to insulation breakdown leading to electrical arcing, which creates combustible gases that build pressure until catastrophic rupture occurs. This is often triggered by overloading, poor maintenance, manufacturing defects, or lightning strikes. Modern transformers include safety features like pressure relief devices to prevent explosions.

After years in the supply chain side of transformer manufacturing, I've seen how these critical components can fail spectacularly when something goes wrong. The consequences extend far beyond just the immediate damage—they affect grid stability, cause business interruptions, and potentially endanger lives. Let me break down the key aspects of transformer explosions and share what I've learned about preventing them.

What Causes Transformers to Explode?

Power transformers contain a perfect storm of risk factors: high voltage electricity, combustible insulating oil, and confined spaces. When these elements interact in unintended ways, disaster follows quickly and violently.

Transformer explosions typically occur when electrical faults cause arcing that decomposes insulating oil into explosive gases. As these gases accumulate and pressure builds beyond containment capacity, the transformer tank ruptures violently. Common triggers include insulation deterioration, manufacturing defects, lightning strikes, and overloading conditions.

In my role at Voltori Energy, I've analyzed numerous failure reports, and the patterns are clear. Insulation breakdown is frequently the primary culprit behind catastrophic failures. What's particularly concerning from a supply chain perspective is how often these failures stem from compromised components or materials that don't meet Canadian specifications.

I remember one particularly alarming case where a wind farm in Alberta experienced a transformer explosion because the manufacturer had substituted lower-grade insulation materials during production. This subtle change wasn't detected until failure occurred. This experience fundamentally changed how we approach material qualification at Voltori Energy, implementing multi-stage verification processes for every component.

The physics behind these explosions is straightforward but devastating. When electrical arcing occurs inside a transformer, it instantly vaporizes surrounding insulating oil. This decomposition creates hydrogen, methane, ethylene and acetylene gases. In confined spaces, pressure builds exponentially until the transformer tank can no longer contain it—resulting in a violent rupture often accompanied by fire as mineral oil ignites.

Key Factors Contributing to Transformer Explosions

| Factor | Description | Prevention Approach |

|---|---|---|

| Insulation Breakdown | Aging or damaged insulation creates pathways for electrical faults | Regular dissolved gas analysis and insulation resistance testing |

| Manufacturing Defects | Poor quality control during production introduces vulnerabilities | Rigorous factory acceptance testing and quality assurance |

| Operational Stresses | Overloading or frequent load fluctuations accelerate deterioration | Proper sizing and application-specific design |

| External Events | Lightning strikes, flooding, or physical damage | Surge protection devices and strategic placement |

How Long Will Power Be Out If a Transformer Blows?

When a transformer explosion occurs, the immediate question everyone asks is: "How long until power returns?" Unfortunately, there's no simple answer—the timeline depends on multiple factors that often involve complex supply chain challenges.

Power outage duration after a transformer explosion typically ranges from 24 hours to several weeks depending on the transformer size, availability of replacements, and extent of collateral damage. Distribution transformers may be replaced in 1-3 days, while large custom power transformers can take months to manufacture and install if no spare is available.

The timeline for power restoration after a transformer explosion varies dramatically based on several interconnected factors. In my experience managing supply chains for power equipment, I've seen firsthand how availability of replacement units becomes the critical path for restoration. At Voltori, we've invested in domestic supply chains that can deliver emergency replacements within 48-72 hours for standard configurations, but I've seen cases where operators without contingency plans faced weeks or even months of downtime due to global supply chain bottlenecks.

The size and customization level of the transformer dramatically impacts replacement timelines. Small distribution transformers might be readily available from regional warehouses, allowing for same-day replacement. Medium-sized units typically take 3-7 days to source and install if they're standard configurations. However, large power transformers, especially those custom-designed for renewable energy applications, present a much greater challenge.

I recall one solar farm project where the main step-up transformer failed catastrophically just two months after commissioning. With no spare available and a 14-week lead time for manufacturing a replacement, the facility operated at reduced capacity using a temporary rental unit that cost nearly $12,000 per day. This experience taught me the importance of strategic spare parts planning—something we now emphasize strongly with all our Voltori Energy customers.

Typical Power Restoration Timelines

| Transformer Type | Typical Outage Duration | Key Limiting Factors |

|---|---|---|

| Distribution (<500 kVA) | 4-24 hours | Crew availability, weather conditions |

| Medium Power (500-5000 kVA) | 1-7 days | Equipment availability, installation complexity |

| Large Power (>5000 kVA) | 1-12 weeks | Manufacturing lead time, transportation logistics |

| Custom-Engineered Units | 3-9 months | Engineering specifications, specialized materials |

What Is the Most Common Cause of Transformer Fires?

Transformer fires represent some of the most dangerous and damaging scenarios in power systems. Understanding the primary causes helps inform both prevention strategies and emergency response protocols.

The most common cause of transformer fires is electrical faults that lead to oil ignition. These faults typically result from insulation breakdown due to aging, contamination, or manufacturing defects. When current flows through unintended paths, it creates intense heat and arcing that ignites the mineral oil used for insulation and cooling.

with emergency response](https://voltoritransformer.com/wp-content/uploads/2025/09/4-image-transformer-fire-with-emergency-respond.png)

Throughout my career overseeing transformer supply chains, I've analyzed numerous post-failure reports, and patterns definitely emerge. The most prevalent cause of transformer fires I've encountered is insulation degradation combined with overloading. This is especially problematic in renewable energy applications where transformers frequently deal with variable inputs from wind or solar sources.

At Voltori Energy, our engineering team has developed specific designs that account for these fluctuations, incorporating more robust insulation systems and conservative thermal ratings. These design considerations directly affect our material sourcing strategies, as we often need to specify higher-grade materials than what might be considered industry standard.

Insulation breakdown creates a dangerous sequence of events: as insulation deteriorates, it allows current to flow through unintended paths. This creates localized heating that accelerates degradation in surrounding materials. Eventually, this process creates a runaway thermal condition where temperatures rise rapidly, decomposing the insulating oil and generating combustible gases. Once temperatures reach oil's flash point (approximately 140-160°C), ignition becomes nearly inevitable.

Another significant factor I've observed is moisture contamination. Even small amounts of water in transformer oil dramatically reduce its dielectric strength and accelerate aging. This is why we've implemented strict moisture control protocols throughout our manufacturing process at Voltori, including vacuum drying chambers and controlled-environment assembly areas.

Common Transformer Fire Causes and Their Relative Frequency

| Cause | Approximate Frequency | Key Indicators |

|---|---|---|

| Insulation Degradation | 35-40% | Increasing dissolved gas levels, higher power factor |

| Overloading | 20-25% | Operating above nameplate rating, accelerated aging |

| Manufacturing Defects | 15-20% | Early-life failures, localized heating patterns |

| Loose Connections | 10-15% | Hot spots at terminals, increasing contact resistance |

| External Events | 5-10% | Lightning strikes, flooding, physical impact |

How Can Transformer Explosions Be Prevented?

Preventing transformer explosions requires a comprehensive approach that begins with design and continues throughout the operational lifecycle. My experience has shown that proactive measures save millions in potential damages and lost productivity.

Transformer explosions can be prevented through a combination of proper design, quality manufacturing, regular maintenance, and monitoring technologies. Key strategies include implementing pressure relief devices, using more stable insulating fluids, conducting regular dissolved gas analysis, ensuring adequate cooling, installing fault detection systems, and following conservative loading practices.

Prevention comes down to three critical factors: proper design for the specific application, rigorous quality control throughout the manufacturing process, and comprehensive monitoring systems once installed. In our Vancouver facility at Voltori Energy, we've implemented a multi-stage testing protocol that catches potential failure points before units are shipped to customers, significantly reducing field failures compared to industry averages.

From a supply chain perspective, prevention begins with material sourcing integrity. One of my first initiatives at Voltori was establishing a supplier qualification program that goes beyond standard certifications. We regularly audit our core suppliers' manufacturing processes and test incoming materials against performance specifications rather than just dimensional conformance. This approach has caught several potential issues that might have resulted in premature failures.

Modern transformer design incorporates numerous safety features specifically targeting explosion prevention. Rapid pressure rise relays can detect abnormal pressure increases and initiate protective shutdowns before catastrophic failure occurs. Buchholz relays monitor gas accumulation within the transformer, providing early warning of internal faults. At Voltori, we've standardized these protective devices even on smaller units where they're sometimes considered optional in the industry.

For renewable energy applications, I've found that transformers require special considerations due to their unique operating environments. Wind farm transformers, for example, experience frequent load fluctuations and harmonics that standard designs may not adequately address. Our renewable energy transformer designs incorporate more conservative thermal ratings and enhanced insulation systems specifically to handle these stresses.

Transformer Explosion Prevention Strategies

| Prevention Strategy | Implementation Approach | Effectiveness |

|---|---|---|

| Design Optimization | Application-specific engineering with safety margins | Very High |

| Material Quality Control | Supplier qualification and incoming inspection | High |

| Monitoring Systems | Online DGA, temperature monitoring, partial discharge detection | Very High |

| Maintenance Programs | Regular oil sampling, thermography, visual inspections | High |

| Loading Management | Conservative operation within nameplate ratings | Medium-High |

| Environmental Protection | Improved cooling, climate control for extreme environments | Medium |

Conclusion

Transformer explosions result from a complex interplay of electrical, thermal, and mechanical factors that can be prevented through proper design, quality construction, and diligent monitoring. Understanding these causes is the first step toward protecting our power infrastructure.

At Voltori Energy, we're committed to building transformers that not only perform efficiently but operate safely for decades in demanding renewable energy applications across Canada.