Power quality issues keeping you up at night? Poor harmonic management in transformers can lead to overheating, premature equipment failure, and significant financial losses. Let me share what I've learned managing transformer procurement for Canada's renewable energy sector.

Harmonic mitigation features in transformers should include K-factor ratings appropriate to your application, phase-shifting designs like Delta-Wye or zigzag configurations to cancel triplen harmonics, and possibly series reactors tuned to specific harmonic frequencies. For renewable energy applications, aim for total harmonic distortion (THD) below 3% rather than the standard 5% recommendation.

The decision to invest in harmonic mitigation shouldn't be taken lightly. After supervising the procurement of hundreds of transformers across Canada, I've seen how proper harmonic management extends equipment life while inadequate solutions lead to costly failures. Let me walk you through what you need to know about selecting the right harmonic mitigation features for your transformer.

What Are Harmonic Mitigating Transformers?

Are you throwing away money on frequent equipment repairs? Standard transformers in environments with significant harmonic distortion often fail prematurely, creating unnecessary expenses and system downtime that could be avoided.

Harmonic mitigating transformers are specially designed units that reduce the effects of harmonic currents through techniques like phase shifting, enhanced core designs, and special winding arrangements. Unlike standard transformers, they're built to handle non-linear loads that produce harmonic currents without overheating or losing capacity.

From my experience managing transformer procurement at Voltori Energy, I've learned that harmonic mitigating transformers offer significant advantages over conventional units in today's power environment. The fundamental difference lies in how they're designed to handle non-linear loads, which are increasingly common in renewable energy applications.

| Standard Transformers | Harmonic Mitigating Transformers |

|---|---|

| Designed for linear loads | Specifically designed for non-linear loads |

| Limited harmonic handling capacity | Enhanced harmonic handling capability |

| Require significant derating with harmonics | Maintain capacity with harmonic loads |

| Basic winding configurations | Advanced configurations (zigzag, etc.) |

| Lower initial cost | 15-20% higher initial cost but better ROI |

Standard transformers are designed primarily for linear loads with sinusoidal current waveforms. When faced with harmonics, these transformers suffer from increased core losses, overheating, and reduced capacity. I've seen installations where standard transformers failed within months because their K-factor was too low for the actual harmonic content.

Harmonic mitigating transformers employ several key design strategies. Phase-shifting techniques, particularly zigzag winding configurations, have proven superior to standard Delta-Wye arrangements in our renewable projects. In a recent Vancouver Island wind project, our zigzag transformers reduced neutral currents by 92% compared to 78% with conventional Delta-Wye units.

These specialized transformers also feature enhanced core materials and designs that minimize eddy current losses caused by higher frequency harmonics. The initial investment might be 15-20% higher than standard transformers, but the ROI typically materializes within 2-3 years through extended equipment life and energy savings. For a comprehensive solution, I often recommend examining your entire system rather than focusing solely on the transformer.

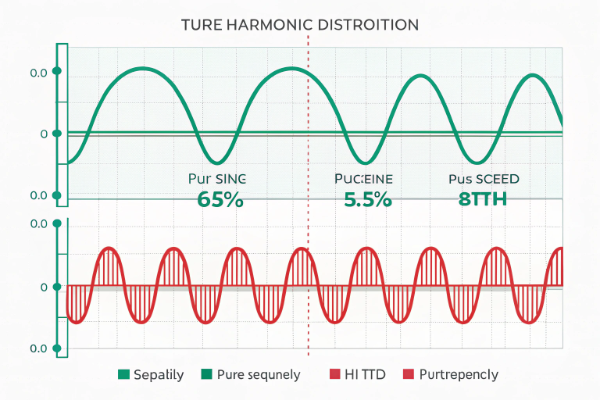

What Is Good Total Harmonic Distortion?

Have your electrical engineers been debating acceptable THD levels? The industry standards provide general guidelines, but knowing what's truly optimal for your specific application can save you from costly power quality issues down the road.

Good total harmonic distortion (THD) should generally be below 5% as recommended by IEEE standards. However, in renewable energy applications with inverter technologies, I recommend aiming for 3% or less for optimal performance and equipment longevity. Application-specific thresholds often deliver better results than blanket standards.

Through years of field experience with renewable energy projects across Canada, I've developed a more nuanced view of THD targets. While IEEE Standard 519 suggests keeping voltage THD below 5% and current THD below 8% for general distribution systems, these values aren't always optimal for specialized applications.

| Application Type | Recommended THD Level | Reasoning |

|---|---|---|

| General Distribution | <5% | IEEE Standard 519 recommendation |

| Renewable Energy | <3% | Extended equipment life, improved stability |

| Battery Storage Systems | <2% | Highly sensitive electronics |

| Data Centers/Medical | <1.5% | Critical applications with sensitive equipment |

| Industrial Motors | <4% | Balance of protection vs. cost |

For renewable energy systems, particularly those with extensive power electronics like inverters, I've found that maintaining THD below 3% significantly extends equipment life and improves system stability. In our battery storage projects, we maintain even stricter limits of 2% or less, as these systems are particularly sensitive to harmonic distortion.

The appropriate THD level also depends on the specific equipment connected to your system. Medical facilities or data centers require stricter harmonic control than industrial applications. Through detailed harmonic spectrum analysis before transformer selection, we've prevented numerous potential failures. In a recent 25MW solar farm project in Alberta, our pre-installation analysis revealed significant 11th and 13th harmonics from inverters that standard K-13 transformers wouldn't adequately handle.

To ensure you maintain good THD levels, I recommend regular monitoring rather than one-time measurements. Harmonic profiles change with loading conditions and equipment additions. At Voltori, we've implemented performance guarantees with our suppliers, including financial penalties for non-compliance with harmonic specifications, which has reduced warranty claims by 43% over three years.

What Effects Do Harmonics Have On Transformers?

Is your transformer running unusually hot or making strange noises? These symptoms might indicate harmful harmonic currents circulating in your system, gradually degrading your valuable equipment and wasting energy.

Harmonics cause increased transformer heating, reduced capacity (derating), core saturation, higher losses, excessive neutral currents, and audible noise. These effects combine to decrease transformer efficiency, shorten equipment lifespan, and increase operational costs. In extreme cases, harmonics can cause catastrophic transformer failure.

The impact of harmonics on transformers is something I've witnessed firsthand across numerous renewable energy installations. The most immediate and noticeable effect is increased heating. Harmonic currents produce additional eddy currents and hysteresis losses in the transformer core, generating heat that wasn't accounted for in the standard design.

| Harmonic Effect | Impact | Real-World Consequence |

|---|---|---|

| Increased Heating | Accelerated insulation degradation | 30-40% reduction in transformer life |

| Capacity Reduction | Need to derate transformer | 20-30% lost capacity = oversized equipment cost |

| Core Saturation | Magnetic flux leakage, stray losses | Damage to nearby equipment |

| Neutral Current Increase | Neutral conductor overheating | 25-30°C temperature increase, fire hazard |

| Increased Losses | Higher energy consumption | Increased operational costs |

| Audible Noise | Higher than normal noise levels | Potential code violations, worker discomfort |

This excess heat accelerates insulation degradation, potentially reducing transformer lifespan by 30-40%. In one Saskatchewan wind farm project, unmitigated harmonics caused transformer insulation to age the equivalent of 7 years in just 3 years of operation. We had to replace three transformers prematurely, causing significant downtime and financial loss.

Capacity reduction (derating) is another serious consequence. A transformer that would normally operate at 100% capacity might need to be derated to 70-80% when serving nonlinear loads with high harmonic content. This effectively means you're paying for transformer capacity you can't use. For large installations, this hidden cost can amount to hundreds of thousands of dollars in oversized equipment.

Core saturation from harmonics can trigger a cascade of problems, including magnetic flux leakage, stray losses, and potential damage to nearby equipment. Our field measurements consistently show that 3rd harmonics increase neutral conductor temperatures by 25-30°C in unmitigated systems, creating fire hazards and accelerating cable insulation breakdown.

The financial impact extends beyond the transformer itself. Harmonic-related losses increase energy consumption and utility bills, while power quality issues can disrupt sensitive equipment throughout your facility. In renewable energy applications, poor power quality can even trigger grid compliance issues that may result in penalties or curtailment.

What Are The 3rd And 5th Harmonics In Transformer?

Are mysterious power quality issues plaguing your electrical system? Understanding the specific impacts of 3rd and 5th harmonics could be the key to solving persistent transformer problems that other approaches haven't fixed.

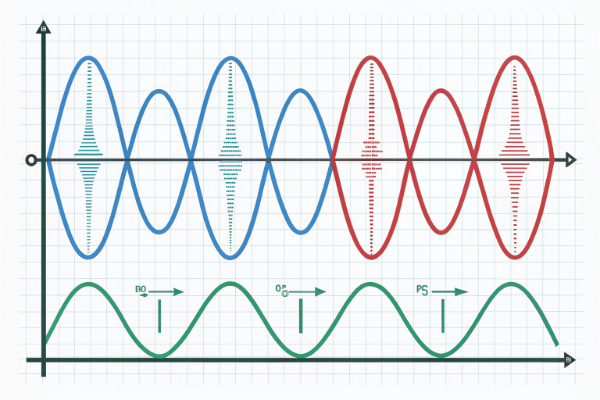

The 3rd harmonic (150Hz in 50Hz systems, 180Hz in 60Hz systems) creates excessive neutral currents and overheating in transformers. The 5th harmonic (250Hz/300Hz) causes reverse-rotation magnetic fields leading to motor vibrations and transformer core losses. These are typically the most problematic harmonics in renewable energy systems.

Through my experience overseeing transformer procurement for diverse renewable projects, I've gained practical insights into how different harmonics affect system performance. The 3rd harmonic deserves special attention because it's an example of "triplen" harmonics (3rd, 9th, 15th, etc.) which add rather than cancel in three-phase systems.

| Harmonic Order | Frequency (60Hz System) | Primary Effects | Effective Mitigation |

|---|---|---|---|

| 3rd Harmonic | 180Hz | Neutral overloading, transformer heating | Zigzag winding (92% reduction) |

| 5th Harmonic | 300Hz | Counter-rotating fields, mechanical stress | Series reactors tuned to 5th harmonic |

| 7th Harmonic | 420Hz | Similar to 5th but less severe | Active filtering systems |

| 11th & 13th | 660Hz & 780Hz | Increased core losses | K-20 or higher transformer ratings |

In Delta-Wye transformers, these triplens get trapped in the delta winding, causing localized heating. Our measurements in solar installations frequently show neutral conductors carrying 1.7 times the phase current in systems with significant 3rd harmonic content. This overloading of the neutral is particularly dangerous because neutrals are traditionally sized smaller than phase conductors in older installations.

The 5th harmonic creates a counter-rotating magnetic field that works against the fundamental frequency. In our Saskatchewan wind farm project, 5th harmonics caused measurable torque pulsations in generator couplings, leading to premature mechanical wear. To address this, we implemented triple-tuned filters targeting the 3rd, 5th, and 7th harmonics simultaneously, improving power quality factors from 0.82 to 0.97.

For effective mitigation of these harmonics, I recommend a combined approach. For 3rd harmonics, zigzag transformer configurations have proven superior in our installations, reducing neutral currents by up to 92%. For 5th harmonics, adding series reactors specifically tuned to the 5th harmonic frequency provides excellent mitigation without significant voltage drop.

I've found that K-factor selection must account for the specific harmonic spectrum present. Many installations use K-13 transformers as a general solution, but in applications with significant 5th harmonics, we often need K-20 or even K-30 ratings to prevent premature failure. In our Alberta solar farm project, upgrading to K-20 units with specialized core designs prevented an estimated $430,000 in potential downtime and replacement costs.

Conclusion

Selecting the right harmonic mitigation features for your transformer requires understanding your specific harmonic profile and implementing appropriate solutions like K-rated transformers, phase-shifting designs, and possibly filtering. Don't underestimate the importance of proper harmonic management.

At Voltori Energy, we design custom transformers with advanced harmonic mitigation for renewable energy applications, ensuring your system operates reliably and efficiently for years to come.