Selecting the wrong transformer type can lead to serious safety hazards, equipment damage, or regulatory non-compliance. Many Canadian renewable energy projects fail inspection due to improper transformer selection.

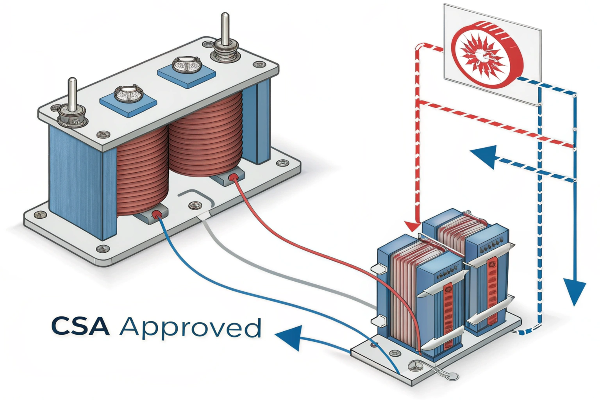

The main difference between autotransformers and isolation transformers is that isolation transformers have separate primary and secondary windings with no electrical connection between them, while autotransformers share a common winding. This makes isolation transformers safer but more expensive than autotransformers.

In my years working with Canadian energy projects, I've seen numerous cases where clients were uncertain about which transformer type would best suit their needs. This confusion isn't surprising – the technical distinctions can be subtle, but the implications for your project's safety, compliance, and performance are significant. Let me break down these differences and help you understand when to use each type in Canadian applications.

What is the difference between isolation transformer and autotransformer?

Safety concerns with electrical equipment keep me up at night. The wrong choice between these transformer types could lead to equipment damage, electrical hazards, or failed inspections.

An isolation transformer has completely separate primary and secondary windings with no electrical connection between them, providing galvanic isolation. An autotransformer uses a single winding that's common to both the primary and secondary circuits, making it more compact and cost-effective but without electrical isolation.

The fundamental difference comes down to physical construction and electrical isolation. When I explain this to clients, I often use a simple analogy: imagine two buckets of water. In an isolation transformer, the water is transferred using a mechanical pump with no direct contact between the water sources. In an autotransformer, some water flows directly between connected buckets.

This structural difference creates several important distinctions:

Safety Considerations

| Feature | Isolation Transformer | Autotransformer |

|---|---|---|

| Electrical Isolation | Complete galvanic isolation | No electrical isolation |

| Ground Fault Protection | Prevents ground faults from passing between circuits | Ground faults can pass between circuits |

| Surge Protection | Better protection against surges and spikes | Limited surge protection capabilities |

Performance Differences

| Aspect | Isolation Transformer | Autotransformer |

|---|---|---|

| Size & Weight | Larger and heavier | More compact (up to 50% smaller) |

| Cost | Higher initial investment | Lower cost (typically 30-40% less) |

| Efficiency | Slightly lower (typically 95-98%) | Higher (can exceed 99%) |

I've personally observed these differences in action during a recent project in Ontario where we needed to address serious harmonic issues while meeting strict local grid isolation requirements. The isolation transformer we designed provided the perfect solution, although it required more installation space than an autotransformer alternative would have.

Which applications can an autotransformer be used for?

The pressure to reduce project costs often tempts my clients to choose autotransformers. I worry they'll make decisions that compromise safety or fail to meet Canadian electrical codes.

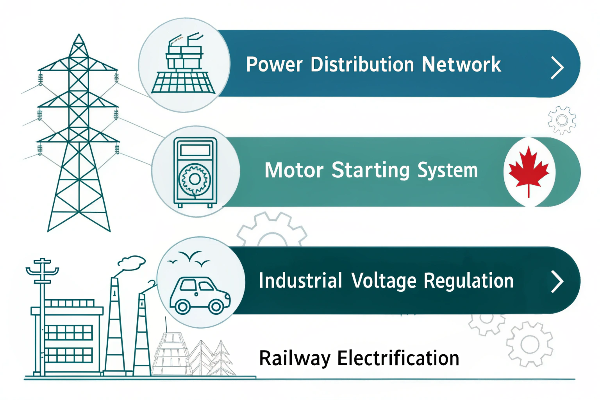

Autotransformers are suitable for voltage conversion within the same system where electrical isolation isn't required, such as adjusting line voltages, voltage correction in power distribution networks, motor starting applications, and certain appliance voltage conversions that don't require safety isolation.

In my experience working across Canada, I've found autotransformers to be excellent solutions in specific scenarios. Their cost-effectiveness and smaller footprint make them attractive options when properly applied.

Ideal Autotransformer Applications in Canadian Settings

Based on Canadian electrical codes and practical field experience, here are the key applications where autotransformers excel:

Power Transmission and Distribution

Autotransformers are workhorses in Canada's power grid, especially for:

- Interconnection of transmission systems operating at different voltages

- Voltage regulation in distribution networks

- Phase conversion in certain industrial settings

Industrial Applications

| Application | Why Autotransformers Work Well |

|---|---|

| Motor Starting | Reduces inrush current by providing reduced voltage starting |

| Furnace Control | Precise voltage control for electric heating elements |

| Voltage Optimization | Energy saving through voltage management |

Specialized Uses

The unique requirements of Canada's diverse regions sometimes call for autotransformers in:

- Remote northern communities with specific power quality needs

- Mining operations requiring voltage conversion without isolation

- Railway electrification projects

I remember installing autotransformers for a manufacturing facility in Quebec where space was extremely limited, but isolation wasn't a safety requirement according to their risk assessment and CSA compliance review. The autotransformer solution saved approximately 40% in costs while meeting all performance parameters.

When should you use an isolation transformer?

I've seen costly mistakes when clients choose autotransformers for applications requiring isolation. Safety regulations, equipment protection, and sensitive electronics can all be compromised by the wrong choice.

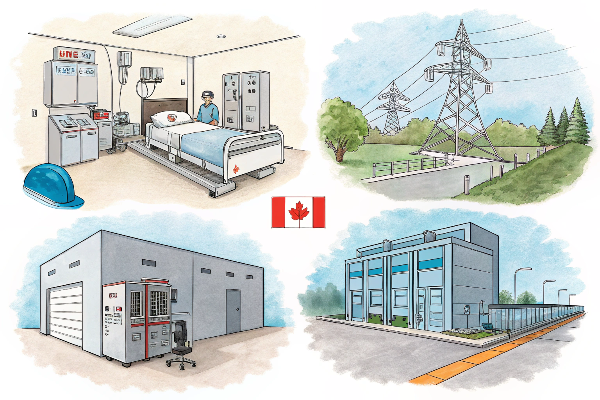

You should use isolation transformers when electrical isolation is essential for safety, noise reduction, or compliance with Canadian electrical codes. This includes medical equipment, sensitive electronics, grounding system separation, protection against harmonics, and any application where personnel safety is paramount.

Throughout my career designing transformer solutions for Canadian renewable energy projects, I've identified several scenarios where isolation transformers aren't just preferred—they're absolutely necessary.

Safety-Critical Applications

Safety must always come first, particularly in these contexts:

- Healthcare facilities: Canadian standards specifically require isolation transformers for patient care areas

- Wet environments: Where electrical isolation provides crucial protection against shock hazards

- Locations with public access: Where additional safety barriers between utility power and accessible equipment are mandated

Technical Requirements

Many technical challenges can only be solved with true isolation:

Noise and Interference Reduction

| Problem | How Isolation Transformers Help |

|---|---|

| Common-mode noise | Blocks transmission between primary and secondary |

| Ground loops | Interrupts paths that cause hum and interference |

| EMI/RFI | Provides significant attenuation of conducted interference |

Power Quality Management

- Harmonic mitigation: Essential for sensitive equipment and compliance with utility requirements

- DC offset elimination: Critical for precision instruments and telecommunications

- Neutral-to-ground voltage control: Important for sensitive electronics and data centers

I recently consulted on a solar farm project in British Columbia where substantial harmonics were wreaking havoc with monitoring equipment. Despite the higher initial cost, we implemented custom-designed isolation transformers that effectively addressed the harmonics while providing the safety isolation required by both the local utility and CSA standards. The long-term reliability gains justified the additional investment.

What is the difference between an autotransformer and a regular transformer?

When clients ask about "regular" transformers versus autotransformers, I notice confusion about basic transformer types that could lead to improper specifications and potential safety issues.

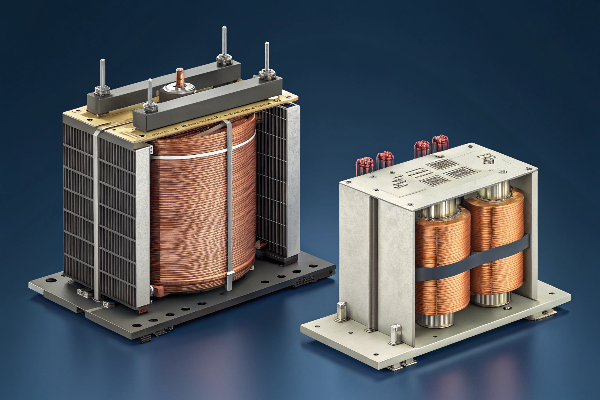

A "regular" transformer (typically referring to an isolation transformer) has separate primary and secondary windings with no electrical connection between them. An autotransformer has a single continuous winding shared between input and output circuits. Regular transformers provide electrical isolation while autotransformers don't.

This distinction is crucial for Canadian applications, where our electrical codes and harsh environmental conditions often influence transformer selection. When clients refer to "regular" transformers, they're typically talking about conventional isolation transformers, which have been the standard for most applications historically.

Structural Differences

The physical construction creates fundamental operational differences:

Winding Configuration

| Transformer Type | Winding Structure | Magnetic Core Usage |

|---|---|---|

| Regular (Isolation) Transformer | Separate primary and secondary | Shared magnetic core, electrically isolated windings |

| Autotransformer | Single continuous winding | Shared magnetic core with electrical continuity between input/output |

Performance Characteristics

These structural differences result in contrasting performance profiles:

- Size and Material Usage: Autotransformers typically use 50-60% less copper and iron than equivalent isolation transformers

- Impedance Characteristics: Autotransformers generally have lower impedance

- Fault Current Behavior: Regular transformers limit fault current transfer between primary and secondary

Canadian Considerations

In my experience with Canadian installations across different provinces, these differences become especially important due to:

- Cold Weather Performance: Insulation and thermal cycling concerns in our northern climate

- Provincial Code Variations: Different requirements across provinces regarding isolation

- Remote Installation Challenges: Size and weight considerations for hard-to-access locations

Working on a wind farm project in Alberta last year, we had to carefully weigh these factors. While the autotransformer option was significantly less expensive, the specific interconnection requirements from the utility mandated electrical isolation. Additionally, the harsh environmental conditions at the site made the robust construction of isolation transformers more suitable for the 25-year expected service life.

Conclusion

Choosing between autotransformers and isolation transformers comes down to your specific safety needs, electrical requirements, and budget constraints. Always consult Canadian electrical codes for your application.

At Voltori Energy, we engineer custom transformers specifically designed for Canadian renewable energy projects, ensuring compliance with all provincial regulations while maximizing efficiency.