Power fluctuations and inefficient energy conversion plague many solar installations. Without proper transformers, your renewable energy investment could be severely underperforming, costing you thousands in lost revenue.

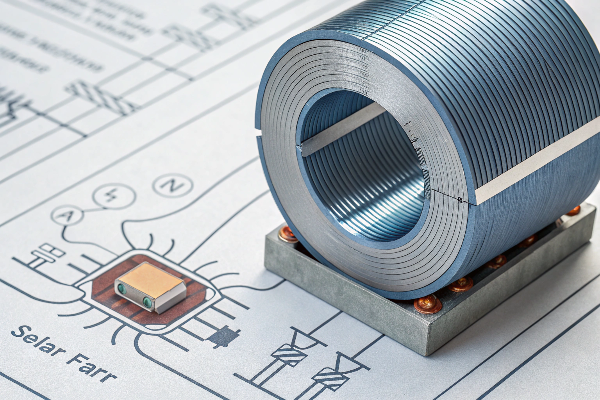

Solar plants typically use transformers with silicon steel cores (CRGO/CRNGO). These cores provide the optimal balance of cost-effectiveness and performance needed to convert the DC power from solar panels into grid-compatible AC power while minimizing energy losses.

When I first started working with solar farm developers, I noticed many were confused about transformer specifications for their projects. This confusion often led to costly mistakes. Let's examine the different aspects of transformers in solar applications to help you make informed decisions for your renewable energy projects.

Which Type of Transformer Is Used in a Solar Plant?

Solar plant operators face significant challenges when integrating their power with the grid. Using the wrong transformer can lead to excessive losses, overheating, and even complete system failure.

Solar plants primarily use three-phase pad-mounted transformers distributed throughout the facility, complemented by 1-2 larger high-voltage main transformers. These transformers handle the voltage step-up from the low voltage generated by solar inverters to medium/high voltage levels for transmission.

I've overseen the installation of dozens of solar plants across Canada, and the transformer configuration typically follows a consistent pattern. At the distributed level, three-phase pad-mounted transformers are strategically placed throughout the solar array fields. These workhorses handle the initial voltage conversion from the inverter outputs (typically 600V or 800V) to medium voltage levels (often 34.5kV).

The number of these pad-mounted transformers depends on the plant's size and design. For a 10MW solar plant, you might have 5-10 distributed transformers. They're usually oil-immersed with ONAN (Oil Natural Air Natural) cooling to withstand outdoor conditions.

For the main interconnection point, larger power transformers (often 40-100MVA) step up the voltage further to transmission levels (69kV, 115kV, or 230kV depending on the grid connection requirements). These main transformers represent critical infrastructure in the solar plant's design.

| Transformer Type | Typical Ratings | Core Material | Key Features |

|---|---|---|---|

| Pad-mounted distribution | 1-3MVA, 600V/34.5kV | Silicon steel | Compact design, outdoor rated |

| Main step-up | 40-100MVA, 34.5kV/115kV+ | Silicon steel | Higher capacity, additional monitoring |

What Is the Transformer in the Solar System?

When investing millions in a solar plant, understanding the critical components becomes essential. Many project managers I've worked with initially underestimate the complexity of the power conversion chain.

A solar system transformer is a specialized electrical device that converts the variable DC power from solar panels (after inverter conversion to AC) into consistent grid-compatible AC power at appropriate voltage levels. It provides isolation, voltage regulation, and enables efficient power transmission.

diagram](https://voltoritransformer.com/wp-content/uploads/2025/07/image-3-solar-system-transformer-diagram-create.png)

During my time designing transformer solutions for renewable energy systems, I've seen the evolution of solar-specific transformer requirements. The transformer in a solar system serves multiple crucial functions beyond simple voltage conversion.

First, it provides galvanic isolation between the solar generation equipment and the utility grid - a critical safety feature. This isolation prevents DC currents from entering the grid and protects equipment on both sides from faults.

Second, the transformer handles voltage regulation, maintaining consistent output despite the inherently variable nature of solar power generation. This regulation is particularly important during cloud coverage events when solar output can fluctuate rapidly.

Third, these transformers must withstand unique operational stresses. Solar plants operate predominantly during daylight hours, meaning transformers experience daily thermal cycling rather than the more consistent loading of traditional power plants. This cycling creates additional stress on insulation systems and structural components.

| Solar Transformer Function | Description | Benefit |

|---|---|---|

| Galvanic isolation | Physical/electrical separation | Prevents fault propagation |

| Voltage conversion | Steps up voltage for efficient transmission | Reduces line losses |

| Harmonics mitigation | Reduces inverter-generated harmonics | Improves power quality |

| Grid stabilization | Helps manage reactive power | Supports grid code compliance |

What Is the Purpose of the Electrostatic Shield in a Transformer?

I've seen numerous solar projects experience inverter failures and grid connection issues. These costly problems often trace back to one overlooked component: the electrostatic shield in transformers.

An electrostatic shield in a transformer intercepts and redirects high-frequency noise and voltage transients between primary and secondary windings. In solar applications, it prevents damaging harmonics from inverters from reaching the grid and protects sensitive electronics from grid disturbances.

placement [electrostatic shield](https://www.maddox.com/resources/articles/electrostatic-shields) in transformer](https://voltoritransformer.com/wp-content/uploads/2025/07/image-4-electrostatic-shield-in-transformer-cre.png)

From my experience specifying transformers for solar projects across Canada, I can confirm that electrostatic shielding is non-negotiable for solar plant transformers. This specialized design feature adds approximately 10% to the transformer cost but delivers essential protection that far outweighs the investment.

Solar inverters, while increasingly sophisticated, generate high-frequency switching noise as they convert DC to AC power. Without proper shielding, this noise can cause premature equipment failure, interfere with control systems, and potentially violate grid interconnection requirements.

The electrostatic shield consists of a conductive material (typically copper) placed between the primary and secondary windings and connected to ground. It works by capacitively coupling high-frequency currents to ground rather than allowing them to transfer between windings.

I recall one 25MW project in Alberta where the developer initially balked at the additional cost for shielded transformers. Six months after commissioning with unshielded units, they faced repeated inverter failures and grid compliance issues. The replacement costs and lost production far exceeded what they would have spent on properly shielded transformers initially.

| Shield Type | Effectiveness | Common Application | Cost Impact |

|---|---|---|---|

| Full copper shield | Highest | Critical solar installations | +10-15% |

| Partial shield | Moderate | Medium-sized installations | +5-8% |

| No shield | None | Not recommended for solar | Base price |

| Double shield | Maximum | Ultra-sensitive installations | +15-20% |

Conclusion

Silicon steel cores remain the standard for solar plant transformers, with electrostatic shielding providing essential protection worth the 10% cost premium. For reliable renewable energy infrastructure that meets Canadian standards, contact Voltori Energy for custom transformer solutions built specifically for your solar project.